OPERATIONS

MANUAL

SUPERIOR

BOLTING SOLUTIONS

SUPERIOR

BOLTING SOLUTIONS

TITAN DEALER

9001 Jameel Rd. Suite 180 | Houston, TX 77040

Toll-Free + 1.866.345.8484 Phone + 1.281.449.9994 Fax + 1.281.449.9996

www.

TITAN

TI

.com

1.866.345.8484

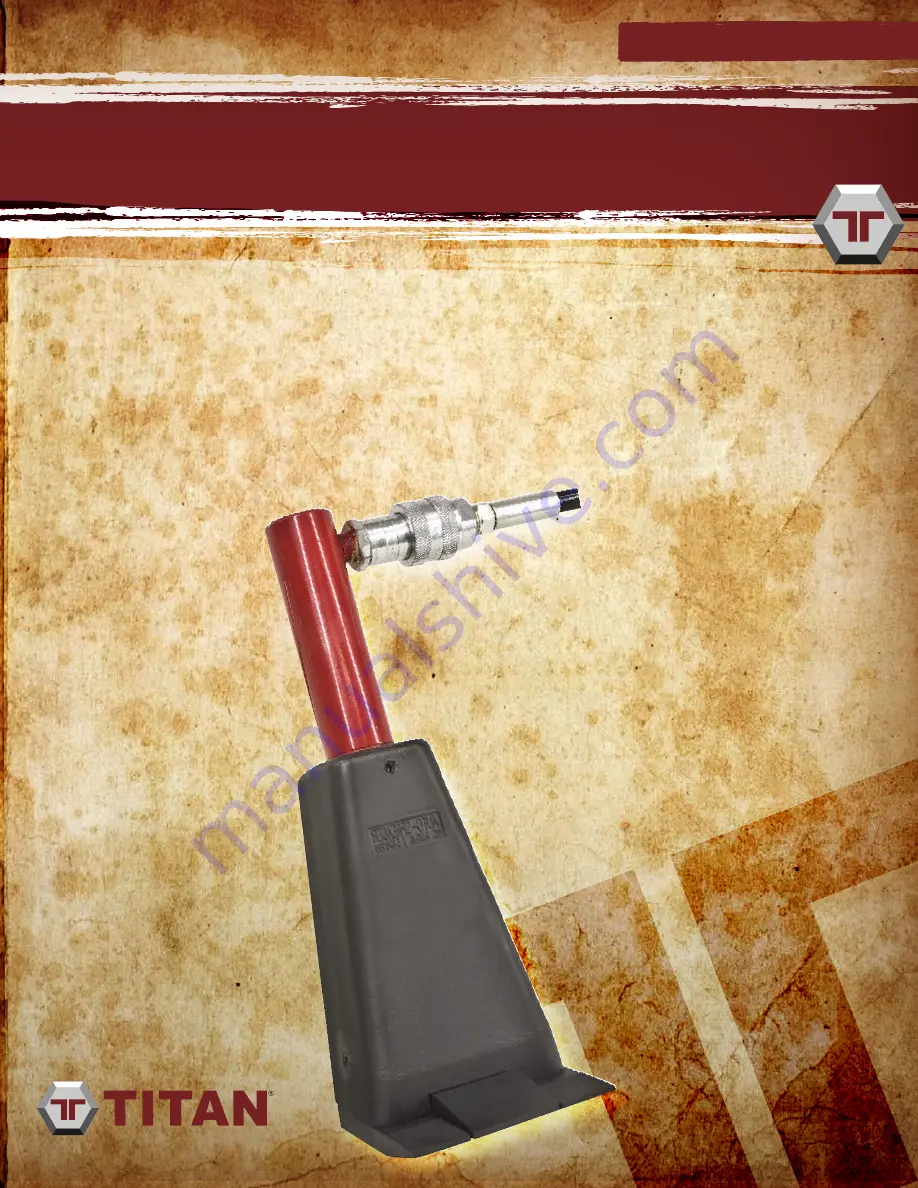

FLANGE

SPREADERS

HYDRAULIC