ORIC

®

Piezo Stage Controller PDXC

Chapter 5: Software

Rev B, September 23, 2021

Page 29

5.3.1. Physical Connection and Set-up

When preparing for the daisy-chain connection, we need to connect all devices in serial

(one device’s daisy-chain

IN port connect to next device’s daisy-chain OUT port on rear panels) by using ethernet cables. Since there is only

one Main in this chain, the to-be-Main device should be the start end of chain, as shown in Figure 5.8.

Figure 5.10 Daisy-Chain Structure

Before we can make them work in chain, each device should be configured to be assign an ID in the daisy chain.

This can be done by connecting each device to the computer via their own USB cable and setting them up in the

software GUI or using command lines. Once the configuration is done, only one USB cable connecting to the Main

device is needed to control the entire chain.

5.3.2. Set Device ID and Connect

Before setting up the daisy chain make sure all units connecting to the chain are working in the same mode, either

in SMC mode or D-Sub mode.

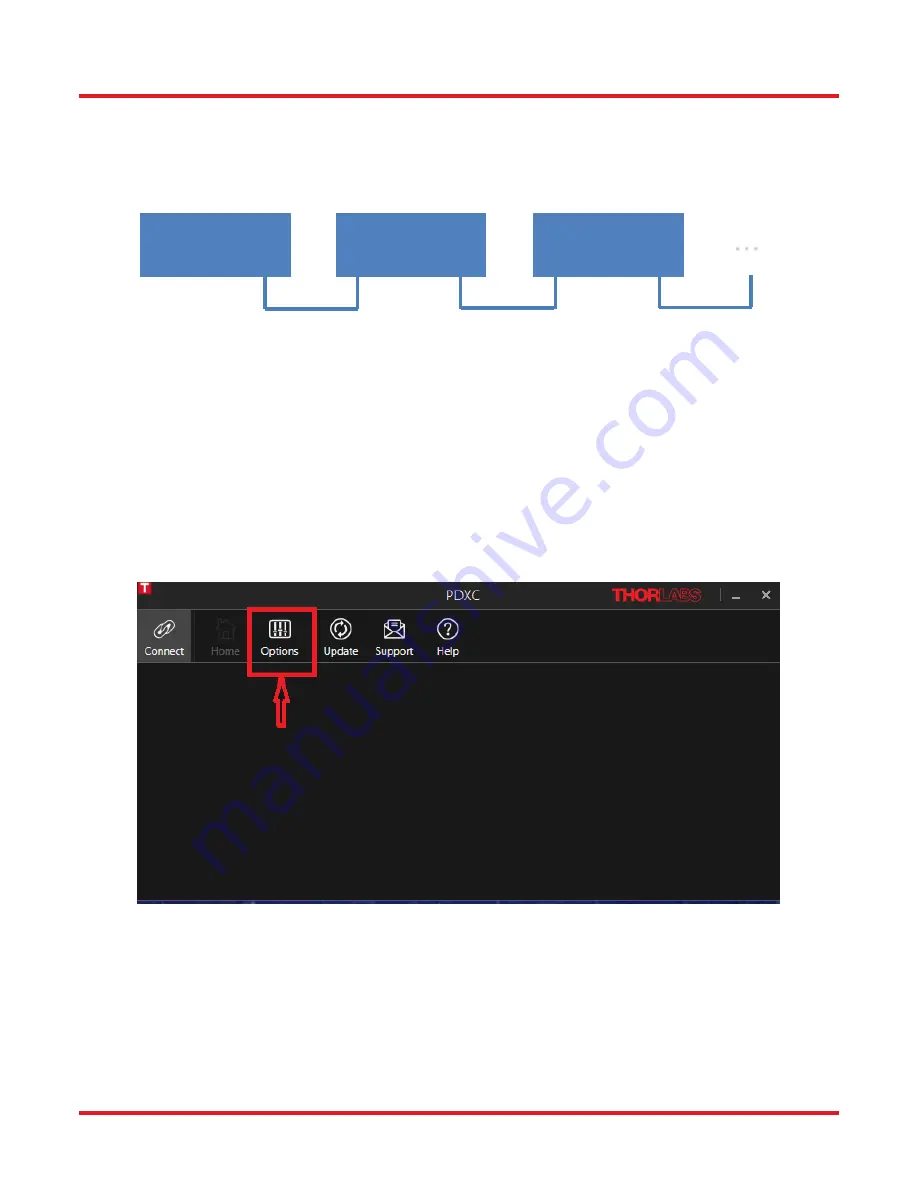

Then power on a unit with a USB cable connected to the PC. Open the software GUI, click the disconnect button

to make sure none units are active in the GUI, then the GUI will show the same window as below.

Figure 5.11 GUI Window after

“Disconnect” Button is Clicked

Open the Options Menu, please check the SN or Port to make sure it is the right device you just connected, and

change the

mode to “Main”.

Main

Daisy Chain

IN

OUT

Secondary 1

Daisy Chain

IN

OUT

Secondary 2

Daisy Chain

IN

OUT

…