7

For more information about our products and how to contact us, please visit thermopatch.com

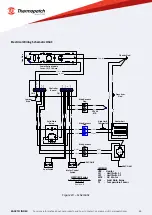

3. Operating the HS-4-C

3.1 Starting up

You can start operating the Thermoseal

HS-4-C as soon as it is connected to the

electricity mains. Switch on the HS-4-C

by pressing the on/off (I-0) switch, which

is placed on the back of the machine, to

“on (I)”. Wait until the set temperature has

been reached, which will take about one

minute.

The Thermoseal HS-4-C has been factory set for:

• Temperature

204°C

• Time

12 seconds

• Power saver timer

30 minutes

• Power saver temperature

149°C

3.2 Functionality

Switch the machine to the “On” position. Either the Celsius or Fahrenheit LED will blink depending upon

the machine settings. The actual temperature of the Heater Element is displayed. During the heat up

phase, and when the machine has achieved “Set Temperature”, changes to the machine settings can be

made for: Set Temperature, Temperature Display in Celsius or Fahrenheit, Sealing Cycle Time, Power Saver

Time and Power Saver Temperature. Changes cannot be made to the machine settings when the machine is

active during a Sealing Cycle.

LCD Display Functions:

The following describes the LCD Display functions and displays: The Celsius or Fahrenheit LED will light up

continuously once the temperature is within range of the setting. Range is +/- 7°C or +/-15°F. When not in a

sealing cycle, the actual temperature of the Heater Element is displayed. During the Sealing Cycle, the LCD

will display a countdown of the time in seconds from the preset Sealing Cycle Time.

Procedure to change desired set temperature:

The SET TEMPERATURE of the HS-4-C heat seal machine has been set at the factory to 204°C.

To change the SET TEMPERATURE, please follow the procedures below:

1. Press select/save button once.

2. Press + or - button to set the desired Set Temperature.

3. Press select/save to save the setting.

Note: If the + or - button is not touched for 3 seconds the display will change to the actual temperature of

the Heater Element and no changes will be saved.

Procedure to change desired Sealing Cycle Time:

The SEALING CYCLE TIME of the HS-4-C heat seal machine has been set at the factory to 12 seconds.

To change the SEALING CYCLE TIME, please follow the procedures below:

1. Press the select/save button twice.

2. Press + or - button to set the desired time.

3. Press select/save to save the setting.