Airplane Factory SLING LSA

Pilot Operating Handbook

Page | 7-30

Date of Issue: 07 July 2014

Revision : 1.3

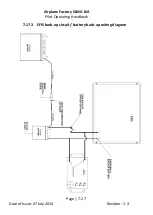

7.20

Lubrication system

For aircraft fitted with the 912 iS engine please refer to the supplement at

the end of this manual.

912 ULS

The engine is provided with a dry sump forced lubrication system with a

camshaft driven main pump with an integrated pressure regulator and oil

pressure sensor. The main pump delivers oil from the oil reservoir, through

an oil cooler (radiator) and oil filter to points of lubrication.

Surplus oil emerging from the points of lubrication gathers at the bottom of

the crankcase from where it is forced back to the oil reservoir by piston

blow-by gasses.

Oil temperature is sensed by a sensor located on the oil pump housing.

The lubrication circuit is vented at the oil reservoir. The oil reservoir is

mounted on the firewall.

Refer to the latest revision / edition of the Rotax 912 ULS engine operator

and maintenance manuals.

The lubrication system volume is approximately 3.5 liters (7.4 pints).

Oil type (912 ULS / 912 iS)

Automotive grade API SG (or higher) type oil, preferably synthetic or semi-

synthetic

.

Refer to the latest revision of the applicable Rotax engine and operator

manuals and the latest revision of the applicable Rotax service bulletins.