©Copyright Task Force Tips LLC 2021

11

LIY-350 January 13, 2021 Rev00

4.5 NOZZLE INSTALLATION

Screw the nozzle onto the monitor’s exit threads.

4.6 PRESSURE GAUGE PORT

There is a ¼” NPT female threaded hole on the back of the monitor and the exit elbow

. The holes are plugged from the

factory. If a pressure gauge is desired, unscrew the plug and install the gage using pipe sealant. Make sure the gauge does not interfere

with operation.

4.7 AUTOMATIC DRAIN

An automatic drain is included to empty water from a low point in the monitor piping to prevent

freezing and help empty hose lines. The valve is designed to close automatically when pressure in

the monitor exceeds approximately 5 psi, and open again when the pressure drops to that point.

The automatic drain may be disabled if not desired for your application.

To disable the drain valve:

1. Unscrew the drain assembly and remove the screw and washer.

2. Flip over the rubber drain valve so the raised edge is against the face of the housing.

Reassemble the screw and washer and reinstall the drain valve assembly.

CAUTION

Mismatched or damaged waterway connections may cause equipment to leak or uncouple under

pressure. Failure could result in injury. Equipment must be mated to matched connections.

CAUTION

Dissimilar metals coupled together can cause galvanic corrosion that can result in the inability to

uncouple the connection, or complete loss of engagement over time. Failure could cause injury. Per

NFPA 1962, if dissimilar metals are left coupled together, an anti-corrosive lubricant should be

applied to the connection and the coupling should be disconnected and inspected at least

quarterly.

WARNING

Monitors, valves, and piping may be damaged if frozen while containing sufficient amounts of

water. Such damage may be difficult to detect visually and can lead to possible damage, injury, or

death. Equipment that may be exposed to freezing conditions must be drained immediately

following use to prevent damage.

CAUTION

Structural damage from corrosion can result from failure to drain appliance between uses. Damage

from corrosion can cause injury due to equipment failure. Always drain appliance between uses.

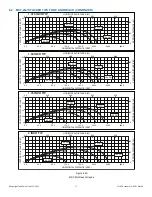

Figure 4.7

Flip this part

over to disable

the drain valve.