Document 57.0300.0200 - 4

th

Edition 07/2000

- Forlì

Page

19

Robot

B-2.2

Qualities of the maintenance staff

The personnel charged with the machine maintenance

shall be qualified, specialised in the maintenance of

earth-moving machines, and shall have the following

requisites:

physical:

good eyesight, acute hearing, good co-ordination and

ability to carry out all required maintenance operations

in a safe way, according to this manual.

mental:

ability to understand and apply the enforced rules, regu-

lations and safety precautions. They shall be careful and

sensible for their own as well as for the others’ safety

and shall desire to carry out the work correctly and in a

responsible way

training:

they shall read and familiarise with this handbook, its

enclosed graphs and diagrams, the identification and

warning plates. They shall be skilled and trained about

the machine functioning.

IMPORTANT

From a technical point of view, the ordinary mainte-

nance of the machine is not a complex intervention

and can be carried out by the machine operator, too,

provided that he has a basic knowledge of mechan-

ics.

B-2.3

Working clothes

During work, but especially when maintaining or repairing

the machine, operators shall wear suitable protective

clothes:

•

Overalls or any other comfortable garments.

Operators should wear neither clothes with large

sleeves nor objects that could get stuck in moving

parts of the machine.

•

Protection helmet.

•

Protection gloves.

•

Working shoes.

•

Safety belt.

IMPORTANT

Use only type-approved working clothes and per-

sonal protective equipment in good condition.

B-2.4 Personal protective equipment

Under special working conditions, the following perso-

nal protective equipment shall be used:

•

Breathing set (or dust mask).

•

Ear-protectors.

•

Goggles or protection masks.

IMPORTANT

Use only type-approved working clothes and per-

sonal protective equipment in good condition.

B-3 SAFETY PRECAUTIONS

B-3.1 Job site

Always take into account the features of the working

area where you are going to work:

•

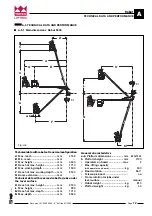

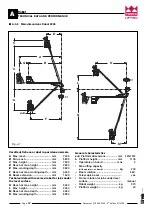

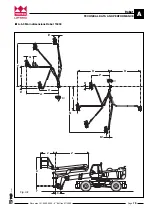

Always examine the working area and compare it

with the overall dimensions of the handler, which the

robot is coupled to, in its different working

configurations.

DANGER

Pay the greatest attention to overhead electric lines.

Always keep a minimum safe distance of at least 6

meters. Danger of electrocution.

•

If you assemble a machine or part of it on site, you

need a fitted area of suitable dimensions. The surface

shall be level, compact and stable.

•

Look for the best route to the working area.

•

When the machine is running, nobody can enter its

working range.

•

During work, keep the working area in order. Never

leave objects scattered: they could hinder the

machine movements and result in dangers for both

personnel and machine.

QUALITIES OF THE PERSONNEL IN CHARGE

B

Summary of Contents for Robot 15000

Page 2: ......

Page 4: ......

Page 6: ...Document 57 0300 0200 4th Edition 07 2000 Forl Page 2 Robot Intentionally blank page...

Page 9: ...Document 57 0300 0200 4th Edition 07 2000 Forl Page 5 Robot Section A GENERAL INFORMATION...

Page 21: ...Document 57 0300 0200 4th Edition 07 2000 Forl Page 17 Robot Section B SAFETY...

Page 25: ...Document 57 0300 0200 4th Edition 07 2000 Forl Page 21 Robot Section C OPERATING INSTRUCTIONS...

Page 37: ...Document 57 0300 0200 4th Edition 07 2000 Forl Page 33 Robot Section D MAINTENANCE...