October 2021

Service and Repair Manual

Platform Components

Part No. 1268515GT

Z

®

-34/22 Bi-Energy

19

2-2

Platform Rotator

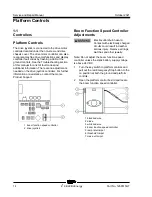

How to Re mov e th e Platfo rm R otat or

How to Remove the Platform

Rotator

Note: When removing a hose assembly or fitting,

the O-ring (if equipped) on the fitting and/or hose

end must be replaced. All connections must be

torqued to specification during installation. Refer to

Specifications,

Hydraulic Hose and Fitting Torque

Specifications.

1 Remove the platform.

2 Tag, disconnect and plug the hydraulic hoses

from the platform rotate manifold.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to

squirt or spray.

3 Support the platform mounting weldment with

a suitable lifting device. Do not apply any

lifting pressure.

4 Remove the six mounting bolts from the

platform mounting weldment. Remove the

center bolt and slide the platform mounting

weldment off of the platform rotator.

5 Support the platform rotator with a suitable

lifting device. Do not apply any lifting

pressure.

6 Remove the pin retaining fasteners from the

jib boom and leveling links to platform rotator

pivot pins. Do not remove the pins.

7 Use a soft metal drift to remove the leveling

link pivot pin. Lower the leveling links to the

ground.

8 Support the jib boom and jib boom lift cylinder

with an overhead crane.

9 Use a soft metal drift to drive both pins out

and remove the platform rotator from the

machine.

Crushing hazard. The jib boom

and jib boom lift cylinder could

fall when when the platform

rotator is removed if not properly

supported by the overhead

crane.

Note: When installing the platform rotator, be sure

to torque the fasteners to specification. Refer to

Specifications,

Machine Torque Specifications.

Summary of Contents for Genie Z-34/22

Page 63: ...October 2021 Service and Repair Manual Manifolds Part No 1268515GT Z 34 22 Bi Energy 51 ...

Page 89: ...October 2021 Service and Repair Manual 77 Electrical Schematic ANSI CSA from SN Z34F 12066 ...

Page 92: ...Service and Repair Manual October 2021 80 Electrical Schematic ANSI CSA from SN Z34F 12066 ...

Page 97: ...October 2021 Service and Repair Manual 85 PBOX Wiring Diagram ANSI CSA from SN Z3414 9686 ...

Page 103: ...October 2021 Service and Repair Manual 91 Electrical Schematic CE AS from SN Z34F 12066 ...

Page 106: ...Service and Repair Manual October 2021 94 Electrical Schematic CE AS from SN Z34F 12066 ...

Page 114: ...Service and Repair Manual October 2021 102 Power Cable Wiring Diagram from SN Z3414 9686 ...

Page 115: ...October 2021 Service and Repair Manual 103 Drive Contactor Panel Wiring Diagram ...

Page 118: ...Service and Repair Manual October 2021 106 Manifold and Limit Switch Wiring Diagram ...

Page 119: ...October 2021 Service and Repair Manual 107 LVI BCI Option Wiring Diagram ...

Page 122: ...Service and Repair Manual October 2021 110 Charger Interlock Option ...

Page 123: ...October 2021 Service and Repair Manual 111 Engine Wiring Diagram ...

Page 126: ...Service and Repair Manual October 2021 114 Contact Alarm Option from SN Z34F 12066 ...

Page 127: ...October 2021 Service and Repair Manual 115 Fuel Level Sensor Option from SN Z34F 12066 ...

Page 129: ...October 2021 Service and Repair Manual 117 Hydraulic Schematic ...

Page 131: ......