MAINTENANCE

6080 330000 (9--97)

46

TIRES (OPTION)

The optional heavy duty rear tires are pneumatic.

Check the rear tires after every 100 hours of

operation for damage. Check the rear tire

pressure after every 100 hours of operation. The

proper tire pressure is 345 kPa (50 psi).

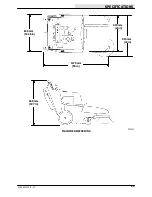

PUSHING AND TRANSPORTING THE

MACHINE

The machine can be pushed in neutral if

necessary.

Tilt trailer or lower the tailgate so the machine can

be driven on to it. Position the machine so it rests

against the front of the trailer. Secure the machine

toward the front of the trailer by wrapping a strap

around the filter compartment and hooking the

ends near the front corners of the machine.

Secure the machine down by wrapping a strap

across the engine compartment and hooking the

ends at the sides of the machine. Place small

pads or cushions under the straps to prevent

machine damage. Make sure the directional

control lever is in the PARK position. Block the

tires to prevent rolling during transport.

STORING MACHINE

When storing the machine for extended periods of

time, the following procedures must be followed:

1. Raise the main and side brush(es).

2. Empty and clean the debris hopper.

3. Drain or disconnect and remove (LPG tank)

fuel system.

4. Close the gasoline valve.

5. Change the engine oil.

6. Remove the spark plug, pour 30 cc (1 oz) of

engine oil into the cylinder. Slowly rotate the

crankshaft to distribute the oil. Replace the

spark plug.

7. Clean the engine cooling fins.

8. Store the machine in a clean dry area.