MAINTENANCE

1550 Gas/LPG/Diesel MM283 (9--01)

3--50

BRAKES AND TIRES

SERVICE BRAKES

The service brakes are hydraulically activated by

a master brake cylinder.

Check the master brake cylinder fluid level after

every 400 hours of operation and add brake fluid

as needed. The master brake cylinder is located

at the front of the machine. Open the front

compartment door for access to the master

cylinder.

If necessary, adjust brake linkage as follows:

adjust clevis on master cylinder push rod so that

brake pedal is in a horizontal position when the

cylinder push rod starts to engage the cylinder

piston.

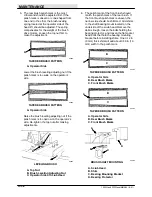

C

B

A

D

F

G

E

00105

BRAKE SYSTEM COMPONENTS

A. Brake Pedal

B. Shaft

C. Pin

D. Master Brake Cylinder

E. Brake Line

F. Push Rod

G. Clevis

Brakes require bleeding whenever air enters the

system, lowering the effective braking pressure.

Air can enter when the master cylinder or wheel

cylinders are serviced or if the fluid in the

reservoir runs dry. Air can also enter through a

leaky brake line or hose. Find the leaking line and

replace it before bleeding.

Whenever handling brake fluid, do not get any on

the brake pads, brake discs, calipers, or body

paint. Brake pads will be permanently damaged,

requiring replacement. Body paint can be

damaged also unless you wipe the area with a

clean cloth and wash it with a soapy solution

immediately.

1. Make sure that the brake fluid reservoir is

full and that the vent in the cap is open.

2. Connect a plastic or rubber tube to the

bleeder valve on the left front wheel.

Suspend the other end of the tube in a jar or

bottle filled with a few inches of brake fluid.

During the remaining steps, keep this end

submerged at all times and never let the

level in the brake fluid reservoir drop below

one half full.

3. Open the bleeder valve and plug on the left

front wheel about one turn. Have an

assistant press the brake pedal slowly to the

floor. As soon as the pedal is all the way

down, close the bleeder valve and let the

pedal up. Repeat this step as many times as

necessary, until fluid with no air bubbles

exits from the tube.

4. Bleed the right front wheel in the same

manner as described in the steps above.

Keep checking the brake fluid reservoir to be

sure it doesn’t run out of fluid.

5. When all wheels are bled, discard the brake

fluid in the jar or bottle; never reuse such

fluid.

6. Top up the brake fluid reservoir with clean

fluid.

Summary of Contents for 1550

Page 16: ...SPECIFICATIONS 1550 Gas LPG Diesel MM283 6 91 1 2 ...

Page 100: ...APPENDIX 1550 Gas LPG Diesel MM283 6 91 4 2 ...

Page 112: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 11 07 6 6 ...

Page 237: ...STANDARD PARTS 6 131 1550 Gas LPG Diesel MM283 3 11 ...

Page 286: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 8 02 6 180 ...

Page 301: ...LPG PARTS 7 15 1550 Gas LPG Diesel MM283 11 07 ...

Page 363: ...DIESEL PARTS 8 53 1550 Gas LPG Diesel MM283 2 05 ...

Page 378: ...DIESEL PARTS 1550 Gas LPG Diesel MM283 2 05 8 68 ...

Page 436: ...BREAKDOWNS 1550 Gas LPG Diesel MM283 8 02 10 38 ...

Page 456: ...CONTINENTAL ENGINE BREAKDOWN GASOLINE LPG 1550 Gas LPG Diesel MM283 2 95 11 20 ...

Page 534: ...PERKINS ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 9 01 15 30 ...

Page 562: ...1011676 CAT ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 2 05 16 28 ...