MAINTENANCE

3--39

1550 Gas/LPG/Diesel MM283 (9--01)

7. Recheck the brush polish marks to see if the

front and rear match, and are even across

the full length of the brush.

8. The width of the rear brush polish mark can

vary more than the desired 2 to 3 in (50 to

75 mm). There are adjusting knobs located

on the drive side of the scrub head. Turn the

knob clockwise to decrease the width of the

polish mark and counterclockwise to

increase the width of the polish mark. The

polish mark should not exceed 3 in (75 mm).

Use the locking strips to keep the adjusting

knobs in place.

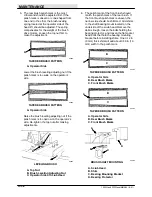

A

B

C

00286

BRUSH ADJUSTMENT KNOBS

A. Locking Strips

B. Front Brush Adjusting Knob

C. Rear Brush Adjusting Knob

9. For maximum brush life, rotate the brushes

from front-to-rear after every 50 hours of

operation.

SCRUB BRUSHES

The scrub brushes are tubular and run the width

of the scrub head sweeping debris into the debris

trough while they scrub the floor. The brushes

should be inspected daily for damage or wear.

Remove any string or wire found tangled on the

scrub brushes, drive or idler hubs.

Rotate the scrub brushes from front-to-rear after

every 50 hours of operation for maximum brush

life and best scrubbing performance.

The scrub brush patterns should be checked

daily. The width of the patterns should be 2 to 3 in

(50 to 75 mm). The scrub brush pattern is

adjusted by turning the adjustment knobs on top

of the scrub head. See

TO ADJUST SCRUB

BRUSH PATTERN

.

TO REPLACE SCRUB BRUSHES

1. Raise scrub head and set scrub head lock.

WARNING: Raised Scrub Head May Fall.

Block Scrub Head Up.

2. Stop engine and set parking brake.

FOR SAFETY: Before Leaving Or

Servicing Machine; Stop On Level

Surface, Set Parking Brake, Turn Off

Machine And Remove Key.

3. Open right side door on scrub head and use

the chain to hold the door in the raised

position.

4. Use wrench to remove hex head bolt

attaching the brush arm.

NOTE: If arm does not come off easily, insert bolt

in the adjacent threaded hole and screw in until

arm comes off.

5. The brush arm and brush can then be pulled

out.

Summary of Contents for 1550

Page 16: ...SPECIFICATIONS 1550 Gas LPG Diesel MM283 6 91 1 2 ...

Page 100: ...APPENDIX 1550 Gas LPG Diesel MM283 6 91 4 2 ...

Page 112: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 11 07 6 6 ...

Page 237: ...STANDARD PARTS 6 131 1550 Gas LPG Diesel MM283 3 11 ...

Page 286: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 8 02 6 180 ...

Page 301: ...LPG PARTS 7 15 1550 Gas LPG Diesel MM283 11 07 ...

Page 363: ...DIESEL PARTS 8 53 1550 Gas LPG Diesel MM283 2 05 ...

Page 378: ...DIESEL PARTS 1550 Gas LPG Diesel MM283 2 05 8 68 ...

Page 436: ...BREAKDOWNS 1550 Gas LPG Diesel MM283 8 02 10 38 ...

Page 456: ...CONTINENTAL ENGINE BREAKDOWN GASOLINE LPG 1550 Gas LPG Diesel MM283 2 95 11 20 ...

Page 534: ...PERKINS ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 9 01 15 30 ...

Page 562: ...1011676 CAT ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 2 05 16 28 ...