MAINTENANCE

3--37

1550 Gas/LPG/Diesel MM283 (9--01)

SCRUB HEAD

SCRUB HEAD

The scrub head houses the two scrub brushes

and the brush drive mechanisms. The scrub head

has two adjustments; scrub head height, and

scrub brush pattern.

The scrub head height adjustment sets the

minimum scrub head height. The height

adjustment should not be changed unless, due to

a major parts replacement or collision, the head

adjustment may have been altered. If the head

height is too low, excessive brush wear, engine

overheating, brush bounce, or excessive brush

drive plug and bearing wear may occur.

The scrub brush pattern adjustment determines

the amount of contact the brush has with the floor.

The brush pattern should be checked daily.

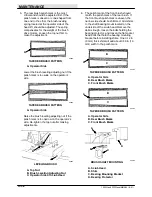

TO ADJUST SCRUB HEAD HEIGHT

1. The head height adjustment must be made

with a full solution tank and tires correctly

inflated; 55 psi (380 kPa) front, 35 psi

(240 kPa) rear.

NOTE: Using a different sized tire on the

machine, other than standard, will affect the head

height adjustment.

2. The head height adjusting nut is located

under the operator’s seat. The nut is

accessible by lifting up the seat. Hold the

seat up by attaching its chain to the steering

wheel.

B

A

03734

ADJUSTMENT NUT

A. Nut

B. Scrub Head Link

3. Adjust the nut so that the top front of the

head is 13.62 in to 13.75 in (345 to 350 mm)

from the floor.

A

B

B

01822

SCRUB HEAD ADJUSTMENT

A. Scrub Head

B. 13.62 to 13.75 in (345 to 350 mm)

4. If the scrub head is lower than 13.62 in

(345 mm), washers should be added below

the adjusting nut.

TO ADJUST SCRUB BRUSH PATTERN

1. The machine must have correct tire

pressures, full solution tank, and correct

scrub head height adjustment.

2. On a smooth, level floor, apply chalk or

some other material that won’t blow away

easily.

3. With the scrub head raised, move the

machine over the test area. Start the brush

rotation, apply the foot brakes, and lower the

scrubber head, allowing the brushes to spin

in one spot for 15 to 20 seconds. With no

chalk or other material on the floor, allow the

brushes to spin approximately two minutes.

4. Polish marks made by both brushes should

be visible. They should be about 1.5 in (40

mm) wide the full length of the brush. With a

soft brush the polish mark should not

exceed 3 in (75 mm) wide, evenly, the full

length of the brush.

Summary of Contents for 1550

Page 16: ...SPECIFICATIONS 1550 Gas LPG Diesel MM283 6 91 1 2 ...

Page 100: ...APPENDIX 1550 Gas LPG Diesel MM283 6 91 4 2 ...

Page 112: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 11 07 6 6 ...

Page 237: ...STANDARD PARTS 6 131 1550 Gas LPG Diesel MM283 3 11 ...

Page 286: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 8 02 6 180 ...

Page 301: ...LPG PARTS 7 15 1550 Gas LPG Diesel MM283 11 07 ...

Page 363: ...DIESEL PARTS 8 53 1550 Gas LPG Diesel MM283 2 05 ...

Page 378: ...DIESEL PARTS 1550 Gas LPG Diesel MM283 2 05 8 68 ...

Page 436: ...BREAKDOWNS 1550 Gas LPG Diesel MM283 8 02 10 38 ...

Page 456: ...CONTINENTAL ENGINE BREAKDOWN GASOLINE LPG 1550 Gas LPG Diesel MM283 2 95 11 20 ...

Page 534: ...PERKINS ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 9 01 15 30 ...

Page 562: ...1011676 CAT ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 2 05 16 28 ...