MAINTENANCE

1550 Gas/LPG/Diesel MM283 (2--05)

3--36

BELTS AND CHAINS

VACUUM FAN DRIVE BELT -- Gas/LPG

ENGINES (For machines below serial number

001508)

VACUUM FAN DRIVE BELT -- DIESEL

ENGINES (For machines serial number 001000

and above)

The vacuum fan drive belt tension should be

checked after every 50 hours of operation. The

proper belt tension for gasoline and LPG

machines is obtained when the midpoint of the

belt deflects 0.34 in (9 mm) from a force of 7 to 8

lb (3.2 to 3.6 kg). The proper belt tension for

diesel machines is obtained when the midpoint of

the belt deflects 8 to 9 lb (3.6 to 4.0 kg).

TO ADJUST VACUUM FAN DRIVE BELT

1. Stop the engine and set the machine

parking brake.

FOR SAFETY: Before Leaving Or

Servicing Machine; Stop On Level

Surface, Set Parking Brake, Turn Off

Machine And Remove Key.

2. Raise the engine cover.

FOR SAFETY: When Servicing Machine,

Avoid Moving Parts. Do Not Wear Loose

Jackets, Shirts, Or Sleeves When

Working On Machine.

3. Loosen the jam nuts on the tension spring

eyebolt.

4. Thread the tension spring eyebolt in to

tighten the vacuum fan drive belt or out to

loosen the vacuum fan drive belt to get the

desired belt tension.

5. Tighten the tension spring eyebolt jam nuts.

6. Lower the engine cover.

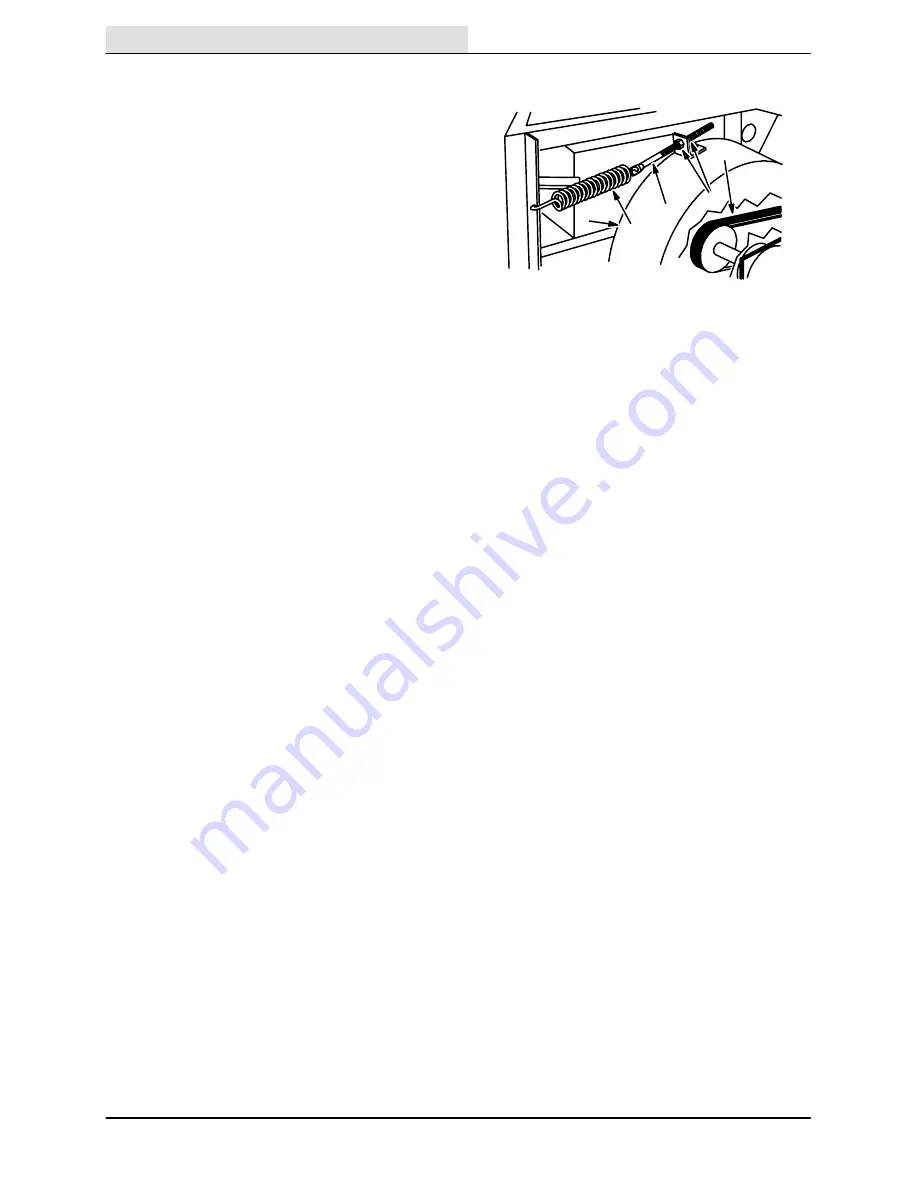

A

B

C

D

E

06973

ADJUSTING VACUUM FAN BELT

A. Vacuum Fan Housing

B. Tension Spring

C. Tension Spring Eyebolt.

D. Jam Nut

E. Vacuum Fan Drive Belt

ALTERNATOR AND RADIATOR FAN BELT

The alternator and radiator fan belt tension should

be checked after every 100 hours of operation.

The proper belt tension is obtained when the

midpoint of the belt’s longest span deflects 0.50 in

(13 mm) from a force of 10 to 12 lb (5 to 6 kg).

TO ADJUST ALTERNATOR AND RADIATOR

FAN BELT

1. Stop the engine and set the machine

parking brake.

FOR SAFETY: Before Leaving Or

Servicing Machine; Stop On Level

Surface, Set Parking Brake, Turn Off

Machine And Remove Key.

2. Open the left rear engine access door.

3. Loosen the alternator clamp bolt.

4. Push the alternator out to tighten the belt.

ATTENTION! Do not use a pry bar

against the alternator to tighten the belt.

Using a pry bar may damage the

alternator.

5. Tighten the alternator clamp bolt.

6. Check the belt deflection; adjust if

necessary.

7. Close the left rear engine access door.

Summary of Contents for 1550

Page 16: ...SPECIFICATIONS 1550 Gas LPG Diesel MM283 6 91 1 2 ...

Page 100: ...APPENDIX 1550 Gas LPG Diesel MM283 6 91 4 2 ...

Page 112: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 11 07 6 6 ...

Page 237: ...STANDARD PARTS 6 131 1550 Gas LPG Diesel MM283 3 11 ...

Page 286: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 8 02 6 180 ...

Page 301: ...LPG PARTS 7 15 1550 Gas LPG Diesel MM283 11 07 ...

Page 363: ...DIESEL PARTS 8 53 1550 Gas LPG Diesel MM283 2 05 ...

Page 378: ...DIESEL PARTS 1550 Gas LPG Diesel MM283 2 05 8 68 ...

Page 436: ...BREAKDOWNS 1550 Gas LPG Diesel MM283 8 02 10 38 ...

Page 456: ...CONTINENTAL ENGINE BREAKDOWN GASOLINE LPG 1550 Gas LPG Diesel MM283 2 95 11 20 ...

Page 534: ...PERKINS ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 9 01 15 30 ...

Page 562: ...1011676 CAT ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 2 05 16 28 ...