MAINTENANCE

1550 Gas/LPG/Diesel MM283 (8--02)

3--32

CYLINDER HEAD -- GASOLINE, LPG

CYLINDER HEAD BOLT TIGHTENING

CONTINENTAL ENGINES

(For machines below serial number 001424)

A three-stage torque procedure should be used

when reassembling the cylinder head. The

cylinder head cap screws and risers must be

tightened in the proper sequence after the first 50

hours of operation and after every 400 hours of

operation.

Snug down cap screws and risers in the proper

sequence. Tighten the cap screws and risers to

one-half of the specified value.

TM27 engines: Hand torque cold M10 bolts to 50

to 55 ft lb (68 to 75 Nm) and M12 bolts to 80 to 85

ft lb (108 to 115 Nm) in the correct order.

01472

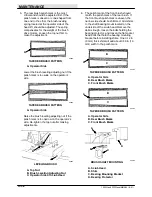

TM27 CYLINDER HEAD BOLT TIGHTENING

SEQUENCE -- CONTINENTAL ENGINES (For

machines below serial number 001424)

The cylinder head cap screws and risers must be

re-torqued after the engine is put into operation

and brought up to proper operating temperatures.

To re-torque cap screws, follow the correct

sequence. Loosen one head cap screw or riser at

a time one quarter turn (90 degrees); then

re-torque it to the correct value.

NOTE: Power wrench torque limit must be held at

least 10 ft lb (14 Nm) below hand torque

specification; then hand torque to the

specifications.

VALVE TAPPET CLEARANCE

The valve tappet clearance must be checked after

the first 50 hours of operation and after every

400 hours of operation.

TM27 engines: Check and adjust the intake

tappets to 0.014 in (0.36 mm) clearance and the

exhaust valve tappets to 0.018 in (0.46 mm)

clearance when the engine is warm and is

operating at idle speed.

CYLINDER HEAD BOLT TIGHTENING --

GM ENGINES (For machines serial number

001424 and above)

A two-stage torque procedure should be used

when reassembling the cylinder head. The

cylinder head cap screws and must be tightened

in the proper sequence after the first 50 hours of

operation and after every 400 hours of operation.

Install the cylinder head bolts finger tight.

Hand torque the cylindrical head bolts to 90 ft lb

(122 Nm) in the correct order.

10

6

2

3

7

9

5

1

4

8

CYLINDER HEAD BOLT TIGHTENING

SEQUENCE -- GM ENGINES (For machines

serial number 001424 and above)

The cylinder head bolts must be re-torqued after

the engine is put into operation and brought up to

proper operating temperatures. To re-torque cap

screws, follow the correct sequence. Loosen one

head cap screw or riser at a time one quarter turn

(90 degrees); then re-torque it to the correct

value. Check the valve tappet clearance.

NOTE: Power wrench torque limit must be held at

least 10 ft lb (14 Nm) below hand torque

specification; then hand torque to the

specifications.

Summary of Contents for 1550

Page 16: ...SPECIFICATIONS 1550 Gas LPG Diesel MM283 6 91 1 2 ...

Page 100: ...APPENDIX 1550 Gas LPG Diesel MM283 6 91 4 2 ...

Page 112: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 11 07 6 6 ...

Page 237: ...STANDARD PARTS 6 131 1550 Gas LPG Diesel MM283 3 11 ...

Page 286: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 8 02 6 180 ...

Page 301: ...LPG PARTS 7 15 1550 Gas LPG Diesel MM283 11 07 ...

Page 363: ...DIESEL PARTS 8 53 1550 Gas LPG Diesel MM283 2 05 ...

Page 378: ...DIESEL PARTS 1550 Gas LPG Diesel MM283 2 05 8 68 ...

Page 436: ...BREAKDOWNS 1550 Gas LPG Diesel MM283 8 02 10 38 ...

Page 456: ...CONTINENTAL ENGINE BREAKDOWN GASOLINE LPG 1550 Gas LPG Diesel MM283 2 95 11 20 ...

Page 534: ...PERKINS ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 9 01 15 30 ...

Page 562: ...1011676 CAT ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 2 05 16 28 ...