MAINTENANCE

3--27

1550 Gas/LPG/Diesel MM283 (8--02)

PRIMING THE FUEL SYSTEM -- CONTINENTAL

ENGINES (For machines serial number

001056--001423)

Priming is necessary on initial installation of the

fuel injection system, after any subsequent

removal, or if the system was drained by running

out of fuel.

Before priming and venting, ensure that the

outside of the vent screws and surrounding area

is thoroughly clean to prevent dirt and foreign

matter entering the system.

NOTE: Electrical equipment such as starters

should be shielded during priming to prevent fuel

entry.

1. Turn the ignition switch to the “on” position.

2. Loosen the filter outlet connection to the fuel

injection pump inlet connection, whichever is

higher, and allow the fuel to flow until free of

air. Tighten the connection.

NOTE: If the filter outlet connection can not be

reached due to the type of filter being used,

loosen the fuel injection pump inlet connection.

3. Loosen any two injector high pressure pipe

nuts at the injector end. Set the accelerator

to the fully “open” position and ensure that

the stop control is in the “run” position.

Crank engine until fuel is free of air bubbles.

Tighten nuts.

NOTE: The bleeding operation may take a

considerable amount of cranking with the starter

to purge all air. It is important that the battery be

in good operating condition when bleeding.

If the engine will not start after bleeding, or any

other time, it may be an indication of a low battery

charge. If the voltage to the fuel shutoff solenoid

falls below 8 volts, the valve will shut off fuel to

the engine. This may happen during cranking if

the battery charge is low. The condition may not

be readily apparent since cranking speed might

still be good.

4. Start the engine.

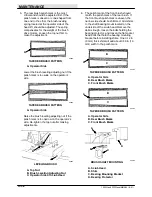

A

B

FUEL SYSTEM SCHEMATIC

A. Fuel Injection Pump Inlet

Connection

B. Filter Outlet Connection

PRIMING THE FUEL SYSTEM -- PERKINS

ENGINES (For machines serial number 001424 --

001505)

Priming is necessary on initial installation of the

fuel injection system, after any subsequent

removal, or if the system was drained by running

out of fuel.

Before priming and venting, ensure that the

outside of the vent screws and surrounding area

is thoroughly clean to prevent dirt and foreign

matter entering the system.

1. Stop the engine and set the machine

parking brake.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, And Turn Off Machine.

2. Fill the fuel tank.

3. Open the side and top engine access doors.

4. Loosen the vent screw on the top of the fuel

filter.

5. Turn the ignition switch on.

Summary of Contents for 1550

Page 16: ...SPECIFICATIONS 1550 Gas LPG Diesel MM283 6 91 1 2 ...

Page 100: ...APPENDIX 1550 Gas LPG Diesel MM283 6 91 4 2 ...

Page 112: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 11 07 6 6 ...

Page 237: ...STANDARD PARTS 6 131 1550 Gas LPG Diesel MM283 3 11 ...

Page 286: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 8 02 6 180 ...

Page 301: ...LPG PARTS 7 15 1550 Gas LPG Diesel MM283 11 07 ...

Page 363: ...DIESEL PARTS 8 53 1550 Gas LPG Diesel MM283 2 05 ...

Page 378: ...DIESEL PARTS 1550 Gas LPG Diesel MM283 2 05 8 68 ...

Page 436: ...BREAKDOWNS 1550 Gas LPG Diesel MM283 8 02 10 38 ...

Page 456: ...CONTINENTAL ENGINE BREAKDOWN GASOLINE LPG 1550 Gas LPG Diesel MM283 2 95 11 20 ...

Page 534: ...PERKINS ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 9 01 15 30 ...

Page 562: ...1011676 CAT ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 2 05 16 28 ...