MAINTENANCE

3--23

1550 Gas/LPG/Diesel MM283 (2--05)

FUEL SYSTEM -- DIESEL

FUEL WATER TRAP

The fuel water trap is located next to the fuel tank.

The water trap should be drained of water daily.

To drain the water trap, unscrew the spigot on the

bottom of the water trap. Drain the water trap of

water. As fuel appears, tighten the spigot to stop

the flow. It may be necessary to bleed the fuel

system of air after draining the water trap.

After every 100 hours of operation, the water trap

must be cleaned as described in

TO CLEAN THE

WATER TRAP

. Replace the water trap filter

element after every 400 hours of operation.

TO CLEAN WATER TRAP

1. Thoroughly clean the exterior of the water

trap.

2. Unscrew the bowl retaining bolt in the center

of the water trap head.

3. Lower the bowl from the water trap head.

Replace the filter element if it is due to be

replaced.

4. Thoroughly clean the water trap bowl in

cleaning fluid.

NOTE: Do not use gasoline to clean the bowl.

5. After cleaning the water trap bowl, fill the

bowl with clean fuel. Hold the water trap

bowl in position under the water trap head.

6. Secure the bowl retaining bolt.

A

B

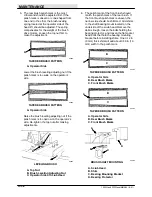

WATER TRAP -- PERKINS ENGINES (For

machines serial number 001424 -- 001505)

A. Water Trap

B. Spigot

7. Prime the fuel system as described in

PRIMING THE FUEL SYSTEM

.

FUEL FILTER

The fuel filter is mounted on the top right side of

the engine. The fuel filter should be replaced after

every 400 hours of operation.

TO REPLACE FUEL FILTER -- CONTINENTAL

ENGINES (For machines between serial number

001000--001055)

1. Thoroughly clean the exterior of the fuel filter

assembly.

2. Unscrew the filter bolt in the center of the

head.

C

D

B

A

01475

FUEL FILTER -- CONTINENTAL ENGINES

(For machines between serial number

001000--001055)

A. Filter Bolt

B. Filter Head

C. Filter Element

D. Filter Bowl

3. Lower the filter bowl and element and

discard the fuel, together with the old

element.

4. Thoroughly clean the filter bowl in cleaning

fluid.

NOTE: Do not use gasoline as a cleaning fluid.

5. Place the new element and sealing rings in

position, fill with clean fuel, and push the

filter bowl up firmly and squarely so that the

top rim of the filter element locates centrally

against the sealing ring in the filter head.

Summary of Contents for 1550

Page 16: ...SPECIFICATIONS 1550 Gas LPG Diesel MM283 6 91 1 2 ...

Page 100: ...APPENDIX 1550 Gas LPG Diesel MM283 6 91 4 2 ...

Page 112: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 11 07 6 6 ...

Page 237: ...STANDARD PARTS 6 131 1550 Gas LPG Diesel MM283 3 11 ...

Page 286: ...STANDARD PARTS 1550 Gas LPG Diesel MM283 8 02 6 180 ...

Page 301: ...LPG PARTS 7 15 1550 Gas LPG Diesel MM283 11 07 ...

Page 363: ...DIESEL PARTS 8 53 1550 Gas LPG Diesel MM283 2 05 ...

Page 378: ...DIESEL PARTS 1550 Gas LPG Diesel MM283 2 05 8 68 ...

Page 436: ...BREAKDOWNS 1550 Gas LPG Diesel MM283 8 02 10 38 ...

Page 456: ...CONTINENTAL ENGINE BREAKDOWN GASOLINE LPG 1550 Gas LPG Diesel MM283 2 95 11 20 ...

Page 534: ...PERKINS ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 9 01 15 30 ...

Page 562: ...1011676 CAT ENGINE BREAKDOWN DIESEL 1550 Gas LPG Diesel MM283 2 05 16 28 ...