6

NOTE: This illustration is for reference only. Unit may differ in appearance or may not include all components shown.

6L]HV

6L]HV

([SDQVLRQ9DOYH$VVHPEO\

7;9

'LVWULEXWRU

25LQJ

'LVWULEXWRU

$VVHPE

l

\

+HDGHU$VVHPE

l

\

25LQJ

7;9

'LVWULEXWRU

'LVWULEXWRU

$VVHPE

l

\

([SDQVLRQ9DOYH$VVHPEO\

3ODWHHDWHU

7UDQVIRUPHU

3ODWH

+HDWHU%ODQN

*URXQG/XJ

7HUPLQDO%ORFN

)XVH

%ORZHU'HFN

&ODPS7XEH

%ORZHU0RWRU

0RWRU6XSSRUW

0RWRU6XSSRUW5LJKW

0RWRU6XSSRUW/HIW

%ORZHU+RXVLQJ:KHHO$VVHPEO\

0RXQW

,

0RWRU

A180051

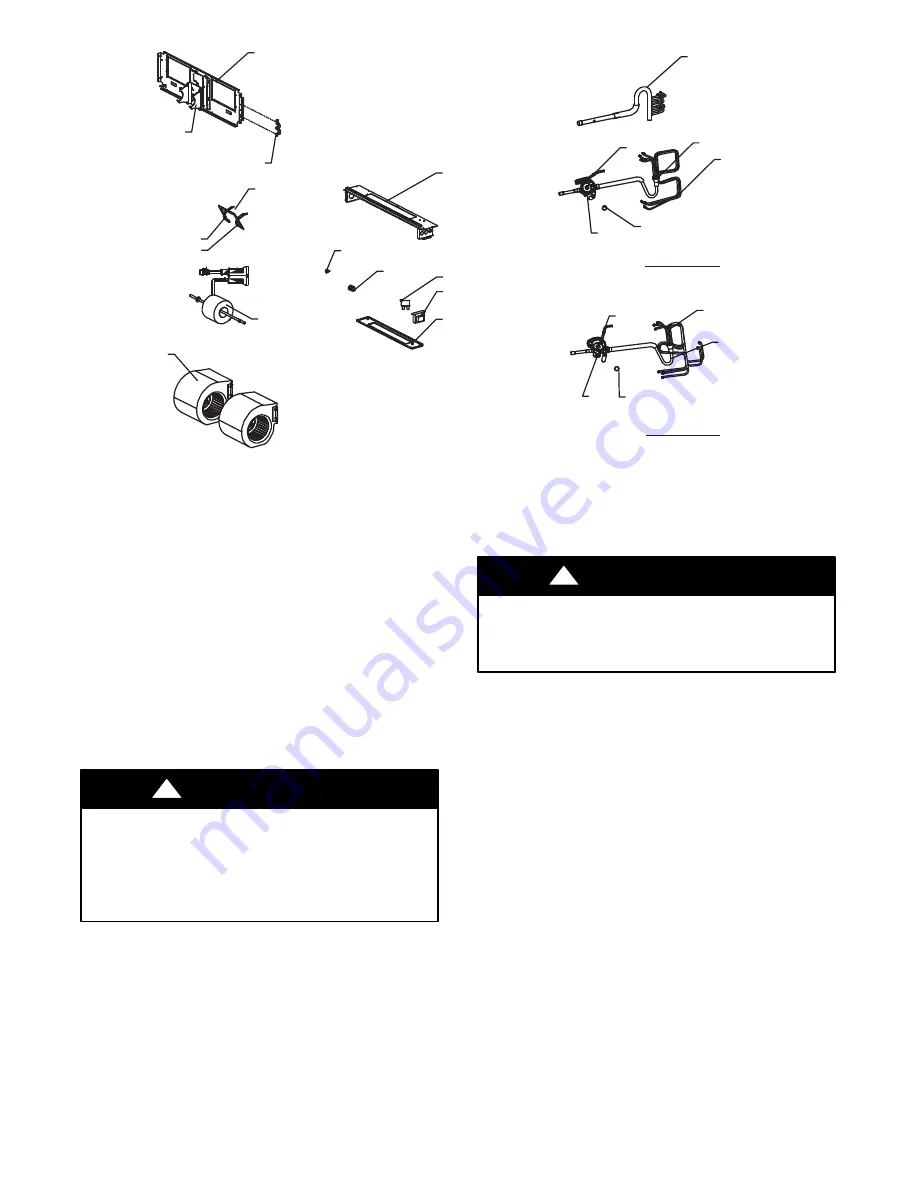

Fig. 6

−

FMU4Z and FMC4Z Models

−

Blower and Coil Parts

CARE AND MAINTENANCE

The minimum maintenance requirements for this equipment are as

follows:

1.

Inspect and clean or replace air filter each month or as re-

quired.

2.

Inspect cooling coil, drain pan, and condensate drain each

cooling season for cleanliness. Clean as necessary.

3.

Inspect blower motor and wheel for cleanliness each heating

and cooling season. Clean as necessary.

4.

Inspect electrical connections for tightness and controls for

proper operation each heating and cooling season. Service

as necessary.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when handling

parts.

CAUTION

!

A. Air Filter

The air filter should be replaced as needed.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage.

Never operate unit without a filter.

CAUTION

!

B. Cooling Coil, Drain Pan, and Condensate Drain

The cooling coil is easily cleaned when it is dry. Inspect coil and

clean (if necessary) before each cooling season. To check or clean

cooling coil, remove blower/heater access panel to gain full access

to cooling coil. If coil is coated with dirt or lint, vacuum with a soft

brush attachment.

Be careful not to bend coil fins. If coil is coated with oil or grease,

clean it with a mild detergent and water solution. Rinse coil with

clear water.

Be careful not to splash water onto insulation.

Inspect drain pan and condensate drain at same time cooling coil is

checked. Clean drain pan and condensate drain by removing any

foreign matter from pan. Flush pan and drain tube with clear water.

If drain tube is restricted, it can generally be cleared by

high

−

pressure water. Cut plastic line and work outside condensate

pan and away from coil to clear drain tube.

NOTE

:

There MUST be a trap in condensate line. Trap must be at

least 3

−

in. deep, not higher than the bottom of unit condensate

drain opening, and pitched downward to an open drain or sump.