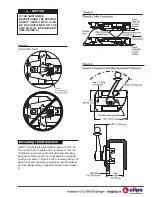

Choose a mounting location for the control head which will pro-

vide comfortable operation of the hand lever, unobstructed move-

ment of mechanism arms and a clear path for cables to engine.

Figure 6 shows the control dimensions and the recommended clearance

behind the mounting surface.

Using the template provided, cut the appropriate mounting hole in the

panel as shown in Figure 7.

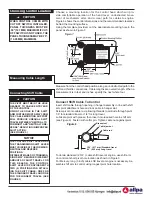

Measure from the control head position along an unobstructed path to the

shift and throttle connections. Cable lengths are overall length. When a

measurement is in feet and inches, specify the next whole foot.

Connect Shift Cable To Control

Insert shift cable through opening in hanger assembly in line with shift

arm pivot attachment hole and lock cable in hanger slot.

Screw pivot onto cable rod, allowing threads to protrude through pivot

1/8” for standard travel or 1/4” for long travel.

Lubricate pivot with grease, then insert into required hole in shift arm

(see Figure 8). Fasten with cotter pin. Tighten cable nut against pivot.

To obtain standard (2 3/4” ) cable shift travel at engine, use shift arm

on control at short pivot hole location as shown in Figure 3.

For Mercury, long (3 inch) cable shift travel at engine is necessary. As-

semble shift arm to control using longest pivot hole location.

CAUTION

!

WHEN CONTROL COMES WITH

CUTOFF SWITCH INSTALLED,

PANEL THICKNESS MUST BE

.50” (12.7 MM) MAXIMUM. IF CUT-

OFF SWITCH IS NOT USED, THE

PANEL THICKNESS MAY BE .75”.

(19.05 MM) MAXIMUM.

Choosing Control Location

Measuring Cable Length

Connecting Shift Cable

CAUTION

!

THE PIVOT MUST BE IN THE HOLE

NEAREST TO CABLE ENTRY END

OF THE CONTROL.

USING THE HOLE IN THE SHIFT

ARM FURTHER MOST AWAY FROM

THE CABLE MOUNTING SUPPORT

WILL PRODUCE UNEQUAL SHIFT

TRAVEL BETWEEN “NEUTRAL TO

FORWARD” AND “NEUTRAL TO RE-

VERSE”, RESULTING IN IMPROPER

SHIFT ACTION.

(SEE FIGURE 3.)

NOTICE

THE CONTROL SHIFT LEVER AND

THE TRANSMISSION SHIFT LEVER

MUST COINCIDE AT THE FORWARD,

NEUTRAL AND REVERSE

POSITIONS.

DIFFERENT MAKES OF TRANSMIS-

SIONS MAY REQUIRE DIFFERENT

AMOUNTS OF SHIFT TRAVEL. FOR

THIS REASON, THE CONTROL

SHIFT LEVER IS PROVIDED WITH

TWO (2) POSITIONS FOR ATTACH-

ING THE SHIFT CABLE: ONE FOR

THE STANDARD TRAVEL AND ONE

FOR THE LONGEST TRAVEL. (SEE

FIGURE 3)

Figure 8

Brass pivot

Cable jam nut

Cable rod

.125" (3.17 mm) Standard travel

.25" (6.35 mm) Long travel