Power Meter Application

NOTE.

This application is available for all instrument models.

The Power Meter application software allows you to make power meter

measurements from a display that emulates a typical bench power meter. Double

click the Power Meter application icon on your Desktop to start the application.

The control panel will appear with default settings applied. You can always return

the software to the default settings state by clicking the

Default Settings

button.

CAUTION.

Do not 23 dBm, 200 mW, or 3.15 VRMS. Ensure that the RF

input connector on the sensor and the mating connector are clean and undamaged.

NOTE.

Using more than one type of application at a time can result in errors. It is

recommended that you use only one type of application at a time.

Front Panel Elements

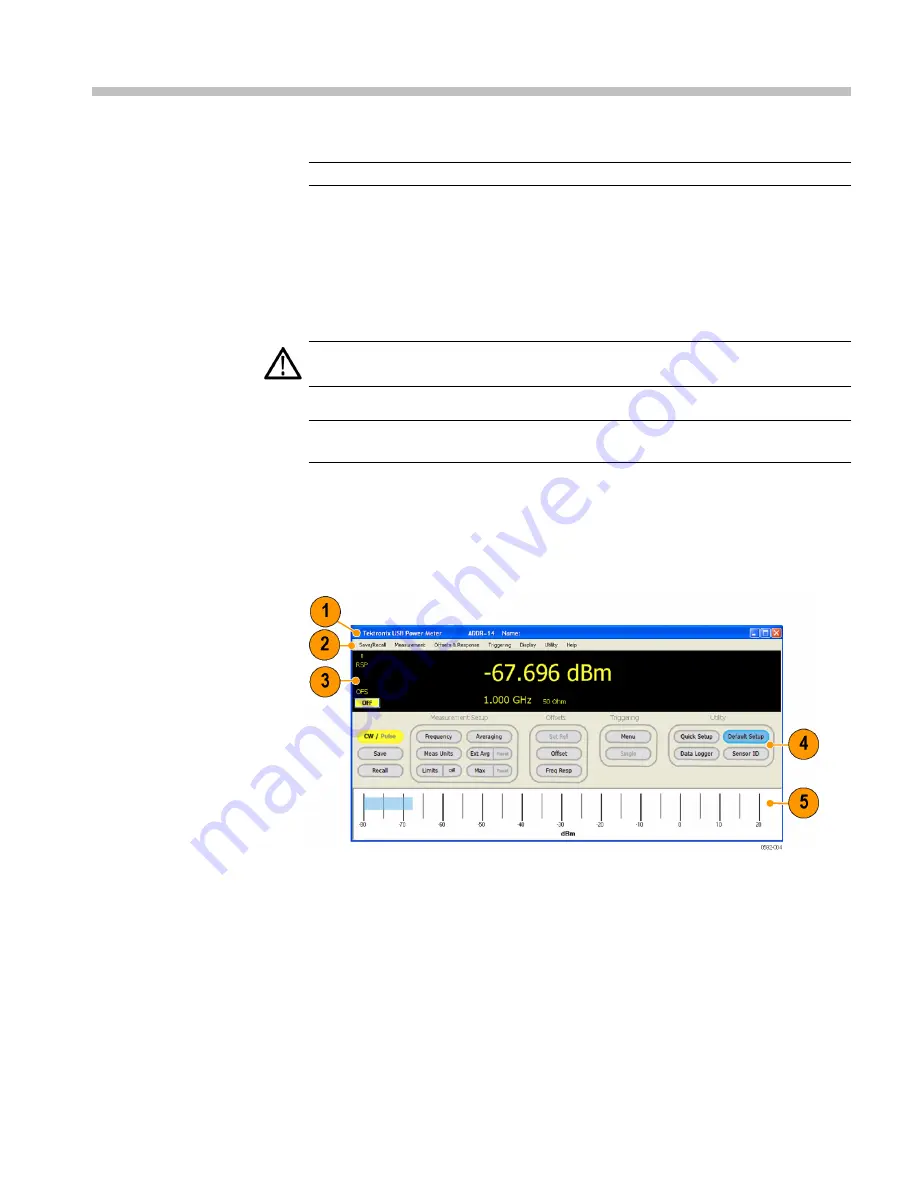

The main elements of the Power Meter application interface are shown here with

no signal applied to the instrument.

Figure 1: Power Meter application interface using a PSM5120

The main elements of the interface are:

1.

Banner: the unit address and the unit name

2.

Menus: drop down menus allow you to adjust various settings; many of these

settings are also accessible using the settings panel buttons

RF and Microwave Power Sensors/Meters

19

Summary of Contents for PSM3000 Series

Page 2: ......

Page 6: ......

Page 10: ...Table of Contents iv RF and Microwave Power Sensors Meters...

Page 14: ...Preface viii RF and Microwave Power Sensors Meters...

Page 26: ...Getting Started 12 RF and Microwave Power Sensors Meters...

Page 32: ...Operating Basics 18 RF and Microwave Power Sensors Meters...

Page 74: ...High Speed Logger Application 60 RF and Microwave Power Sensors Meters...