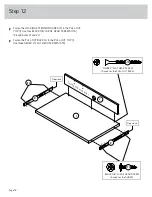

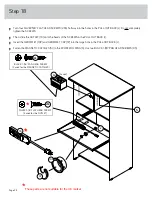

Step 14

L

L

Open end

å

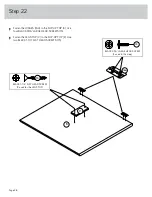

Separate the EXTENSION SLIDES (40MC) from the EXTENSION RAILS (40MA) as

shown in the upper diagram below. Be prepared, the parts are greasy.

å

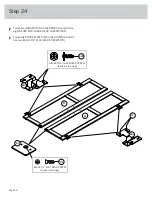

Fasten the EXTENSION RAILS (40MA) to the OUTER UPRIGHTS (L). Use four

GOLD 5/16" FLAT HEAD SCREWS (3S) through holes #1 and #4.

å

NOTE: For each EXTENSION RAIL, turn a SCREW into the hole shown in the

enlarged diagram. Then, slide the inner cartridge of the EXTENSION RAIL in to find

the other hole that lines up with the hole in the OUTER UPRIGHT. Turn a SCREW

into this hole.

å

NOTE: The EXTENSION SLIDES will be used later for the INNER UPRIGHTS.

Push the black lever in and pull the SLIDE from the RAIL.

40MA

40MC

Open end

GOLD 5/16" FLAT HEAD SCREW

(4 used for the RAILS)

3S

3

2

1

1

2

3

4

4

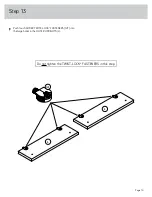

These

TWIST-LOCK®

FASTENERS

must be here.

Page 20