24

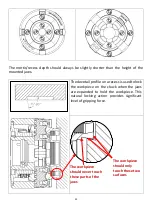

The maximum speed allowed for a mortis/recess varies with the type of intended

operation. This would mostly be based upon the user experience of the user, size of

material being turned, quality of the material being turned and how balanced the

piece is. Therefore, consult with a skilled professional for the maximum speed limits

for your workpiece if you are not confident with your chucking technique.

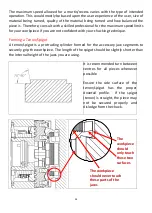

Forming a Tenon/Spigot

A tenon/spigot is a protruding cylinder formed for the accessory jaw segments to

securely grip the workpiece. The length of the spigot should be slightly shorter than

the internal height of the jaws you are using.

It is recommended turn between

centres for all pieces whenever

possible

Ensure the side surface of the

tenon/spigot has the proper

dovetail profile. If the spigot

(tenon) is straight, the piece may

not be secured properly and

dislodge from the chuck.

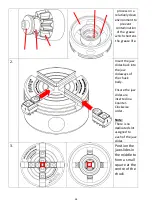

The workpiece

should never touch

these parts of the

jaws

The

workpiece

should

only touch

these two

surfaces