33

CS

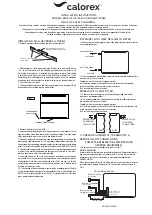

UNIT DESCRIPT

I

ON

FRAME

All units are made from galvanised thick sheet metal, painted with polyurethane powder enamel at

180°C to ensure the best resistance against the atmospheric agents. The frame is self-supporting with

anodized extruded aluminum profiles. The condensate pan is present standard in all CS units and it’s

in stainless steel.

REFRIGERANT CIRCUIT

The refrigerant gas used in these units is R410A. The refrigerant circuit is made in according to 97/23

CE concerning welding procedures and PED regulation.

The refrigerant circuit includes:

•

filter drier;

•

schrader valves for maintenance and control;

•

pressure safety device (according to PED regulation);

•

thermal expansion valve with external equalizer;

•

compressor;

CONDENSER AND EVAPORATORS

FINNED PACK

It consist of copper tubes mechanically expanded into aluminium or copper fins provided with

fullcollars that allow their regular spacing. The best heat transmission is guaranteed by the fincollars

that completely cover the tubes.

FINS

They are manufactured by high precision pressing of aluminium epoxy painted, or pre tinned copper

sheets. The fin shape is slightly corrugated inorder to improve the heat exchange transmission

coefficient withouth heavily affecting the air pressuredrop. Furthermore a good waterdraining is

assures and the inside dust accumulation is avoided.

TUBES

For the heat exchangers high quality copper tubes are used. The tubes are suitable for the majority of

the primary refrigerant and both cold and warm working conditions.

COMPRESSOR

The compressor is scroll type with crankcase heater and thermal overload protection by a klaxon

embedded in the motor winding.

The characteristics of the compressor are the follow:

1. High efficiency for saving energy consumption;

2. Low sound level for quiet operation;

3. Applied HFC refrigerant for protecting environment;

4. High reliability, long lifetime;

FANS

Centrifugal fan type and fan-motor direct coupled.