Chapter 7 Hardware Specification

197

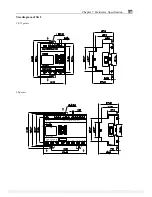

24V DC, 20 I/O model

content

SG2-20HR-D & SG2-20KR-D

SG2-20HT-D & SG2-20KT-D

Normal digital input

High speed input

Analog input used

as normal digital

input

Analog input

Input

circuitry

I03~I08

I01,I02

I09,I0A,I0B,I0C

number 6

2

4

4

Signal

current

input

3.1mA/24V DC

3.1mA/24V DC

0.63mA/24V

<0.17 mA/10V

ON current

input

>1.875mA/15V >1.875mA/15V

>0.163mA/9.8V

OFF current

input

< 0.625mA/5V

< 0.625mA/5V

< 0.083mA/5V

wire length

< / = 100 m

< / = 100 m

< / = 100 m

< / = 30 m(shield wire)

On=>Off On=>Off

On=>Off

5ms 0.5ms

Typical:

5ms

Off=>On Off=>On

Off=>On

response

time of

input

3ms 0.3ms

Typical:

3ms

Input

voltage

0~10

V

DC

Precision

class

0.01V

DC

bit of

conversion

12

error

±2%±0.12V

Conversion

time

1

cycle

sensor

resistance

<1K

ohm

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor