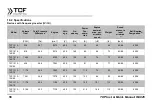

60

TXP Inst. & Maint. Manual: IM-825

Position

Name

1

Hexagon Nut ISO 4032

2

Disc DIN 125

3

Motor

4

Hexagon Screw with Flange DIN 6921

5

Fan Flange

6

Hex Bolt ISO 4017

7

Fan Housing

8

Impeller

9

Disc

10

Cylinder Head Screw DIN 7984

11

Cover

12

Protective Grille

13

Hex Bolt ISO4017

14

Hexagon Nut ISO 4032

15

Disc DIN125

16

Isolator

17

Console

Table 13: Spare Parts

Contact Twin City Fan & Blower for an individual spare parts

list.

To do this, you need the serial number (see performance plate)

of the device.