27 |

P a g e

G e n e r a l D a t a H e a l t h c a r e , I n c .

•

With each turn the

specimen holding arm

will also advance forward by

the set trim thickness at the top most position.

•

If the retract function is turned on, the

specimen holding arm

will

retract backwards a set amount when the arm is at its lowest position to

prevent the specimen from being scrapped by the blade on its way up.

•

The

specimen holding arm

will then advance forward the full retract

amount plus the set trim thickness amount.

•

To obtain optimum quality sections, the following factors need to be taken into consideration:

a.

The hardness of the specimen.

b.

The angle of the cutting blade.

c.

Whether the blade is clamped tightly.

d.

Whether the specimen is clamped tightly.

•

To obtain a quality section, first adjust the proper angle of the cutting blade and the specimen:

a.

The smaller the angle, the less the section will be compressed.

b.

The harder the specimen, the larger the angle will be needed.

c.

If the section is not good, please try increasing the angle from zero.

When finished sectioning, turn the hand wheel until the specimen is in the upper most

position. Lock the hand wheel, remove the blade and dispose of it safely.

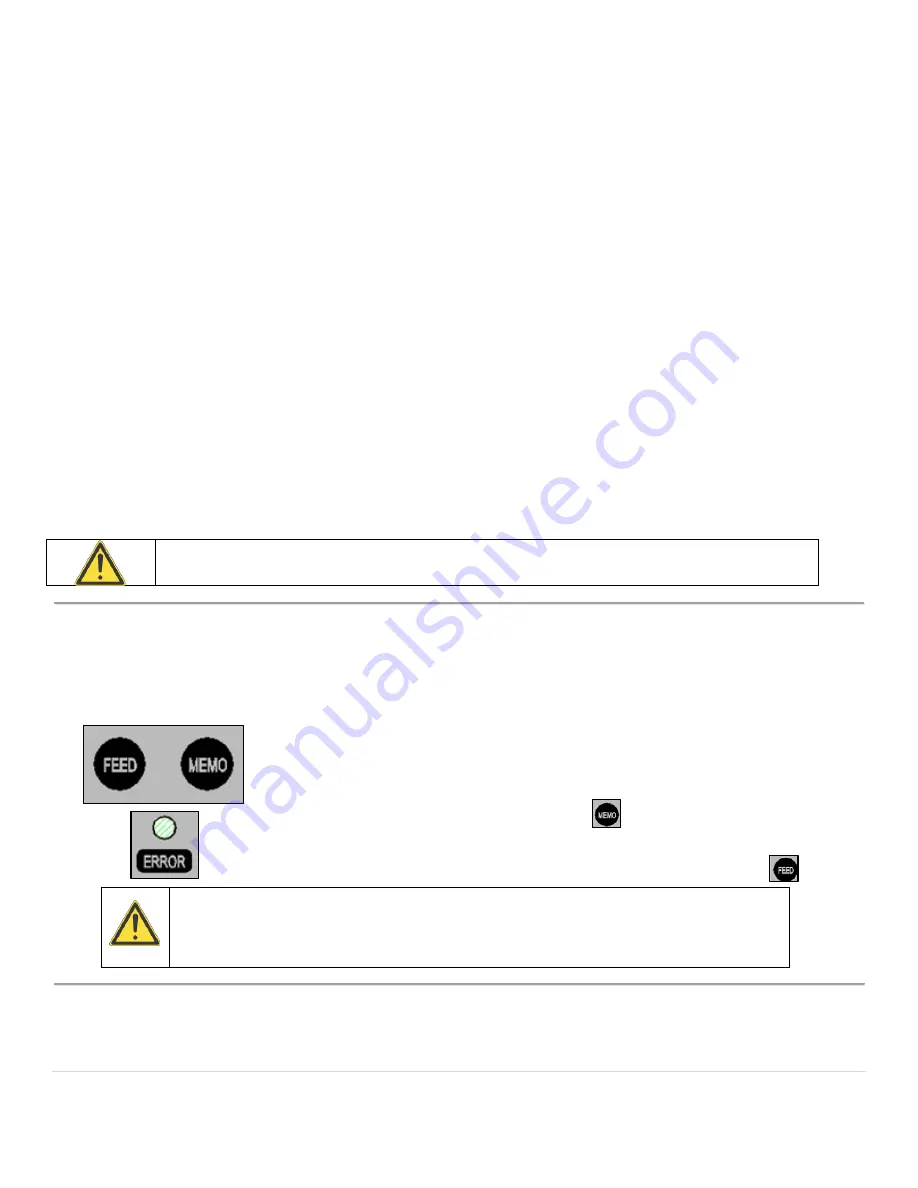

Memorized Feed Function

•

Memorized feed function allows for the operator to switch between

specimens, readjust the specimen holding arm forwards or backwards,

and then return back to the first specimen and be able to quickly recall

the memorized position of the specimen holding arm allowing for a

quick restart in trimming / sectioning.

•

To activate the feed memory function, move the specimen arm to the

desired position and then press the

button. The operator can now

change the specimen if desired and readjust the arm.

•

To move the arm back to the memorized position, press the

button.

Make sure that the hand wheel is locked in its upper most position when recalling

the memorized position or else an alarm will sound and the ERROR LED indicator

will illuminate.