6-14

OPERATING PROCEDURES

Models C709 & C717

Operating Procedures

6

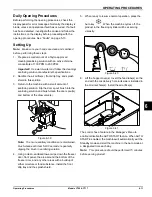

Brush-Cleaning

1.

Prepare a sink of Taylor-approved cleaning/sanitizing

solution with an active chlorine concentrate of

100 PPM to 200 PPM.

Important!

Use warm water and follow the cleaning/

sanitizing solution manufacturer's specifications.

Make sure all brushes provided with the machine are

available for brush cleaning.

2.

Remove all O-rings.

3.

Thoroughly brush-clean all disassembled parts in the

cleaning solution, making sure all lubricant and mix

film is removed. Make sure to brush all surfaces and

holes, especially the draw valve hole in the freezer

door.

4.

Rinse all parts with clean, warm water. Place the

parts on a clean, dry surface to air-dry overnight.

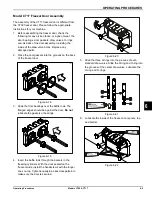

5. Return to the machine with a small amount of

cleaning solution. Using the black brush, clean the

rear shell bearing at the back of the freezing cylinder.

Figure 6-46

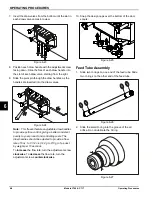

6.

Repeat steps 1 through 5

for the other side of the

C717.

7. Wipe all exterior surfaces of the machine with a

clean, sanitized towel.

10014

Summary of Contents for C709

Page 8: ...1 4 TO THE INSTALLER Models C709 C717 To the Installer 1 Notes...

Page 22: ...4 10 OPERATOR PARTS IDENTIFICATION Models C709 C717 Operator Parts Identification 4 Notes...

Page 58: ...8 4 TROUBLESHOOTING GUIDE Models C709 C717 Troubleshooting Guide 8 Notes...

Page 60: ...9 2 PARTS REPLACEMENT SCHEDULE Models C709 C717 Parts Replacement Schedule 9 Notes...

Page 64: ...10 4 LIMITED WARRANTY ON EQUIPMENT Models C709 C717 Limited Warranty on Equipment 10 Notes...

Page 68: ...11 4 LIMITED WARRANTY ON PARTS Models C709 C717 Limited Warranty on Parts 11 Notes...