OPERATING PROCEDURES

6-13

Models C709 & C717

Operating Procedures

6

3.

Open the draw valve on the freezer door. Drain all the

rinse water from the door spout. Close the draw

valve, and press the Wash key,

/

canceling the Wash mode.

4.

Repeat this procedure using clean, warm water, until

the water being discharged is clear.

5.

Repeat steps 1 through 4

for the other side of the

C717.

Hopper Cleaning

1.

Prepare a 2-1/2 gal. (9.5 L) pail of a Taylor-approved

cleaning/sanitizing solution with an active chlorine

concentrate of 100 PPM to 200 PPM.

Important!

Use warm water and follow the cleaning/

sanitizing solution manufacturer's specifications.

2.

Pour the solution into the hopper and allow it to flow

into the freezing cylinder.

3.

Using the white hopper brush, clean the mix hopper,

mix-level sensing probes, and the outside of the

agitator driveshaft housing. Using the double-ended

brush, clean the mix inlet hole.

Note:

Do not brush-clean the mix inlet hole while

the machine is in the Wash mode.

4.

Press the Wash key

/

. The cleaning

solution in the freezing cylinder will contact all areas

of the freezing cylinder.

5.

Place an empty pail beneath the door spout(s).

6.

Open the draw valve on the freezer door and draw off

all the solution.

7.

Once the cleaning solution stops flowing from the

door spout, close the draw valve and press the

Wash key

/

, canceling the Wash mode.

8.

Repeat steps 1 through 7

for the other side of the

C717.

Disassembly

Note:

Failure to remove the parts specified below for

brush-cleaning and lubrication will result in damage to

the machine. These parts must be removed within the

maximum number of days allowed between brush-clean

cycles, or the machine will hard lock and will not operate.

WARNING!

Make sure the power switch is in

the OFF position! Failure to follow this instruction may

result in severe personal injury to fingers or hands from

hazardous moving parts.

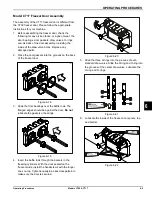

1. Remove the handscrews, freezer door, beater,

scraper blades, and driveshaft with driveshaft seal

from the freezing cylinder.

2. Remove the scraper blades.

3. Remove the driveshaft seal from the driveshaft.

4. Remove the freezer door gasket(s), front bearing(s),

pivot pin(s), draw handle(s), and draw valve(s).

Remove the three O-rings from the draw valve(s).

5.

Model C717:

Remove the design caps.

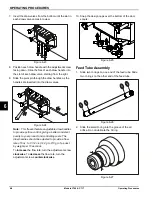

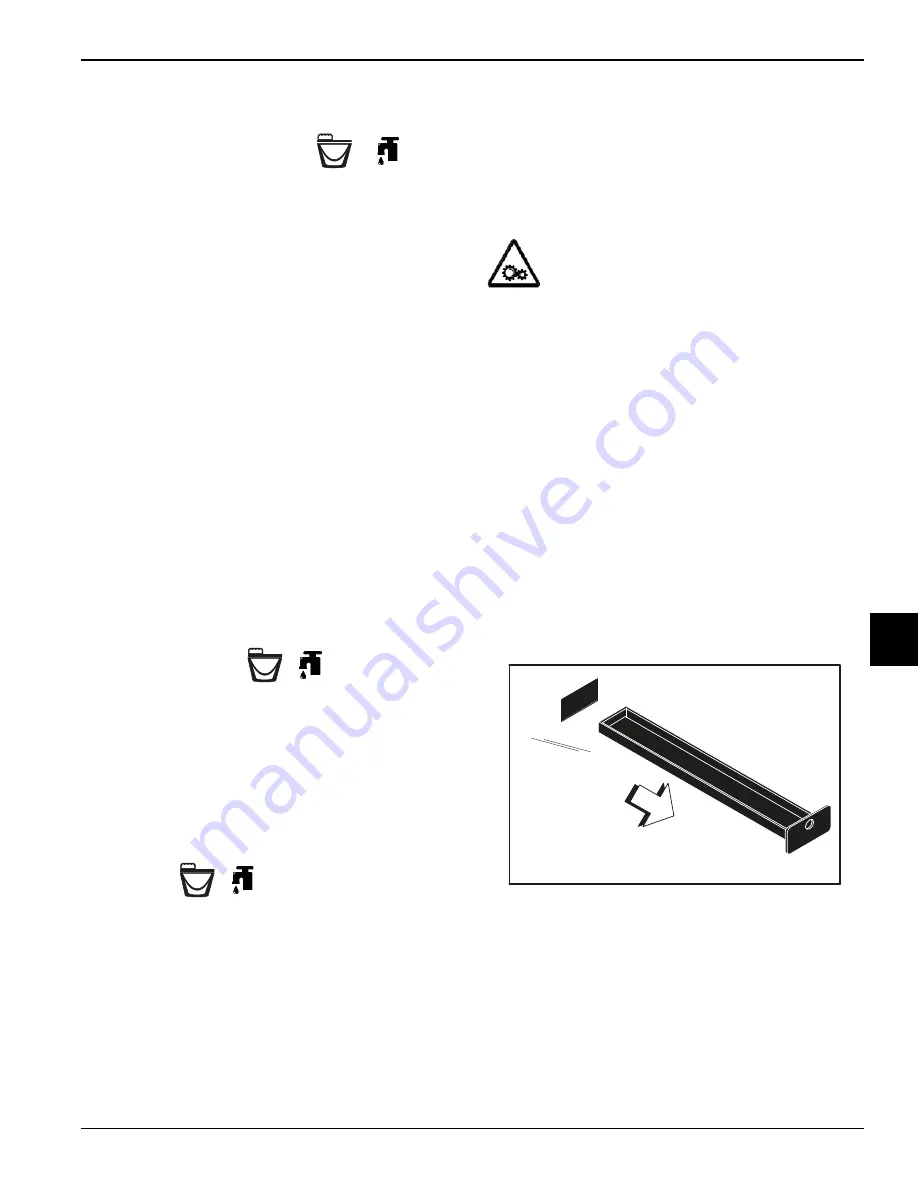

6. Remove the front drip tray and splash shield.

7. Remove all drip pans and take them to the sink for

cleaning.

Figure 6-45

Note:

If the drip pans are filled with an excessive

amount of mix, the driveshaft seal(s) or O-ring(s)

should be replaced or properly lubricated.

8.

Repeat steps 1 through 7

for the other side of the

C717.

10176

Summary of Contents for C709

Page 8: ...1 4 TO THE INSTALLER Models C709 C717 To the Installer 1 Notes...

Page 22: ...4 10 OPERATOR PARTS IDENTIFICATION Models C709 C717 Operator Parts Identification 4 Notes...

Page 58: ...8 4 TROUBLESHOOTING GUIDE Models C709 C717 Troubleshooting Guide 8 Notes...

Page 60: ...9 2 PARTS REPLACEMENT SCHEDULE Models C709 C717 Parts Replacement Schedule 9 Notes...

Page 64: ...10 4 LIMITED WARRANTY ON EQUIPMENT Models C709 C717 Limited Warranty on Equipment 10 Notes...

Page 68: ...11 4 LIMITED WARRANTY ON PARTS Models C709 C717 Limited Warranty on Parts 11 Notes...