19

Model 432 Tim Hortons

Operating Procedures

150123

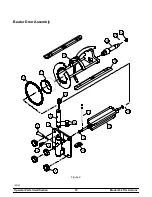

Step 14

Place the rounded side of the large rubber gasket

into the groove on the back side of the freezer door.

Slide the white, plastic front bearing onto the bearing

hub, making certain that the flanged end of the

bearing is resting against the freezer door. DO NOT

lubricate the door gasket or front bearing.

Figure 19

IMPORTANT: The door gasket must be installed

with the rounded side in the groove on the back

side of the door. If the door gasket is incorrectly

installed, mix can leak from the freezing cylinder.

Step 15

Place the front end of the torque rotor into the hole

in the center of the door. Position the door onto the

four studs on the front of the freezing cylinder. Raise

the lever that rests on top of the draw valve and

push the door into place. Install the four handscrews

onto the door and tighten them equally in a

criss-cross manner to ensure the door is snug. DO

NOT over-tighten the handscrews.

Note: Be sure to lift the draw lever when placing the

door into position. Failure to do so may cause a

failure to the related components.

Figure 20

Step 16

Position the torque arm by inserting it through the

slot in the torque switch arm and down into the hole

in the torque rotor which protrudes from the door.

Verify proper installation by moving the torque arm

back and forth to be sure it moves freely and easily.

Figure 21

Step 17

Install the front drip pans. Slide the long drip pans

into the holes in the front panel.

Figure 22

Repeat these steps for the other side of the unit.