6-2

OPERATING PROCEDURES

Model 104

Operating Procedures

6

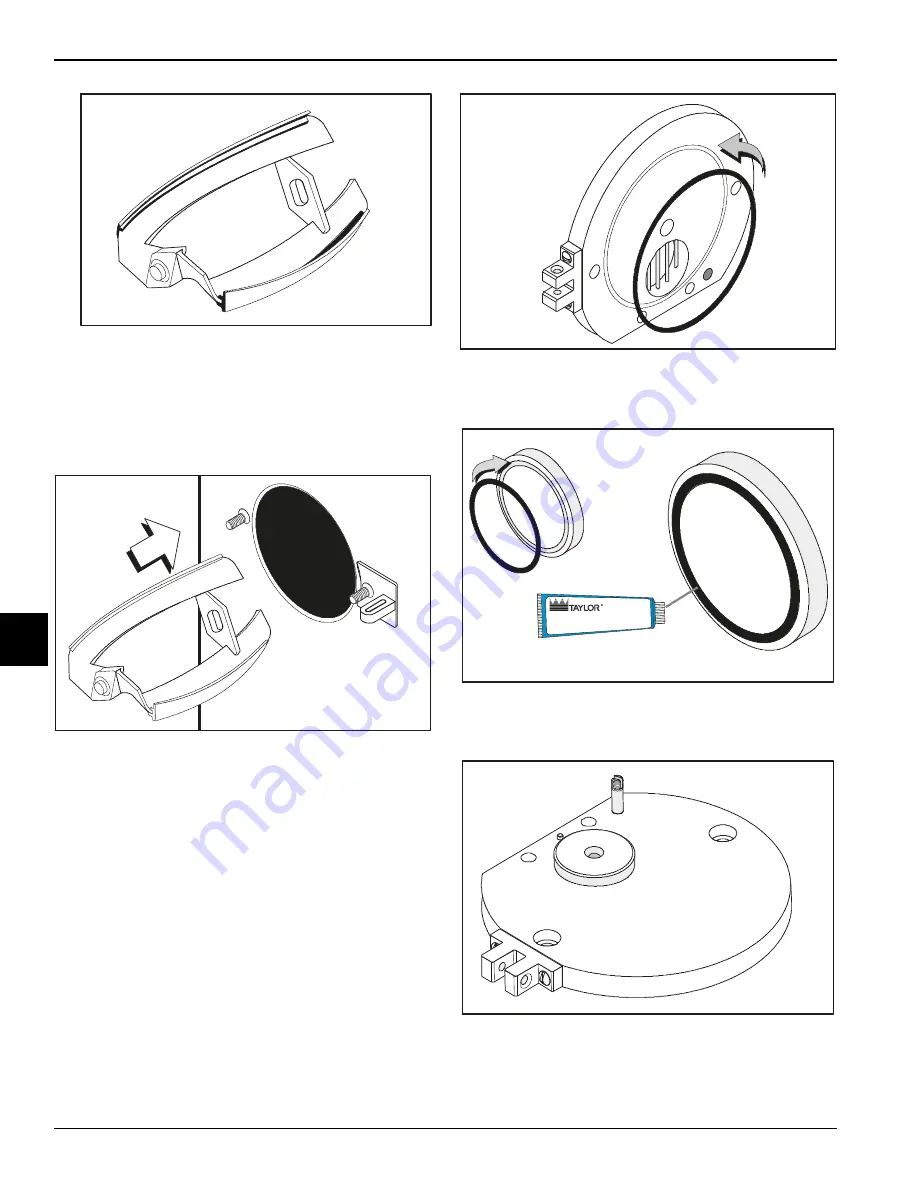

Figure 6-4

4. Holding the beater and blades securely, slide the

beater into the freezing cylinder about one-third of

the way in. Looking into the freezing cylinder, align

the hole at the rear of the beater with the flats on the

end of the driveshaft.

Figure 6-5

5. Slide the beater the remainder of the way into the

freezing cylinder and over the driveshaft. The beater

should fit snugly but not so tightly that the beater

cannot be turned to engage the driveshaft. When in

position, the beater does not protrude beyond the

front of the freezing cylinder.

6. Assemble the freezer door. Place the large freezer

door O-ring in the groove on the back of the freezer

door.

Figure 6-6

7. Press the O-ring into the groove on the back of the

freezer door and lubricate

lightly.

Figure 6-7

8. Lay the draw plate and O-ring facedown over the

ejection port.

Figure 6-8

9. Align the hole in the draw arm over the stem on the

freezer door and push down. Make sure the draw

arm fits into the depression in the draw plate.

11084

10138

11085

11086

Apply the appropriate

Taylor approved food safe lubricant.

11087

Summary of Contents for 104

Page 8: ...1 4 TO THE INSTALLER Model 104 To the Installer 1 Notes...

Page 14: ...3 4 SAFETY Model 104 Safety 3 Notes...

Page 18: ...4 4 PARTS Model 104 Parts 4 Notes...

Page 30: ...7 2 OPERATOR CHECKLIST Model 104 Operator Checklist 7 Notes...

Page 32: ...8 2 TROUBLESHOOTING Model 104 Troubleshooting 8 Notes...

Page 34: ...9 2 PARTS REPLACEMENT SCHEDULE Model 104 Parts Replacement Schedule 9 Notes...

Page 40: ...11 4 LIMITED WARRANTY ON PARTS Model 104 Limited Warranty on Parts 11 Notes...