©Copyright Task Force Tips LLC 2010-2021

5

LIU-330 February 15, 2021 Rev09

3.0 GENERAL INFORMATION

TFT’s 125 Series Eductors can be used with 1/4% or 1/2% Class A foam concentrate for wildland, rural, and urban fire suppression on

Class A fuels (wood, paper, combustible materials). Class A concentrates that have received USDA and USFS approval are

recommended.

On class B materials, the eductors can be used with high viscosity 1%, 3%, 6%, 3x3%, and 3x6% Alcohol Resistant Class B

concentrates.

The eductor can also be used with plain AFFF concentrates rated at 1%, 3% or 6% with various freeze protected foams, and with FFFP

foam types. These foams generally have a lower viscosity than the calibration viscosity of the TFT eductor and will be inducted faster

than expected resulting in stronger concentrations. While this does not degrade foam quality, it does reduce the operation time for a

given foam supply. Testing should be done with the foam being used to assure accurate induction rate.

Standard inlet operating pressure is 200 psi (13.8 bar) on all standard TFT 125 Series Eductors. Contact the factory for custom inlet

pressures of 160 psi (11 bar) and 145 psi (10 bar).

3.1 USE WITH SALT WATER

Consult foam manufacturer’s documentation and training by the Authority Having Jurisdiction (AHJ) before mixing foam concentrate with

salt water.

If the equipment is used with salt water, it must be thoroughly cleaned with fresh water after each use. The service life of the equipment

may be shortened due to the effects of corrosion, and is not covered under warranty.

3.2 VARIOUS MODELS AND TERMS

TFT 125 Series Eductors are available in several flows and with a variety of inlet couplings. These must be specified at the time of order.

Consult the factory for special thread requests.

The eductor can be split into two parts by grasping the locking ring and retracting it fully to separate the metering head from the eductor

body. All the foam passageways can easily be inspected. The foam passageway into the eductor contains a free-floating check disk with

three fins. The check disk is pressure activated to keep water from coming out of the pick-up hose and back into the foam pail.

The metering head contains a red back flush button that can be depressed to open the check disk.

The metering head also has a large proportioning knob that can be rotated to align the ball valve to six different detent positions, OFF,

1/4% 1/2%, 1%, 3%, and 6%. Each foam setting has a precision sized metering orifice in the valve ball. The eductor cannot be operated

between settings, as the metering orifices will not line up properly. The setting of the proportioning knob lines up with the white indicator

ball.

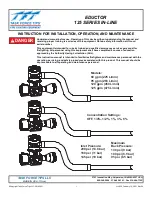

Figure 3.2

CAUTION

Intermixing metering heads and eductor bodies of different flow rates can cause incorrect foam

strength, resulting in risk of injury as the ability to control the fire is compromised. Do not intermix

metering heads with eductor bodies of different flow rates.

PROPORTIONING INDICATOR

36" LONG 1" ID CLEAR HOSE

(Not to Scale)

20" LONG 1" OD WAND

(Not to Scale)

EDUCTOR BODY

EXIT

METERING HEAD

RETRACT THE LOCKER RING

TO UNLOCK.

RELEASE THE LOCKER RING

TO ENGAGE.

TURN KNOB TO SET

PROPORTIONING RATE.

PUSH BUTTON TO

BACK FLUSH.

CHECK DISK