6. Trouble shooting

IOM manual

–

SPT series

27

6.

Trouble shooting

DANGER:

Personal injury hazard. Troubleshooting a live control panel exposes personnel to hazardous

voltages. Electrical troubleshooting must be done by a qualified electrician. Failure to follow

these instructions will result in serious personal injury, death, and/or property damage.

WARNING:

Always disconnect and lock out power before servicing to prevent unexpected startup. Failure

to do so could result in death or serious injury.

Read this manual carefully before requesting repair. After re-inspecting the pump, if it does not

operate normally, contact Tapflo.

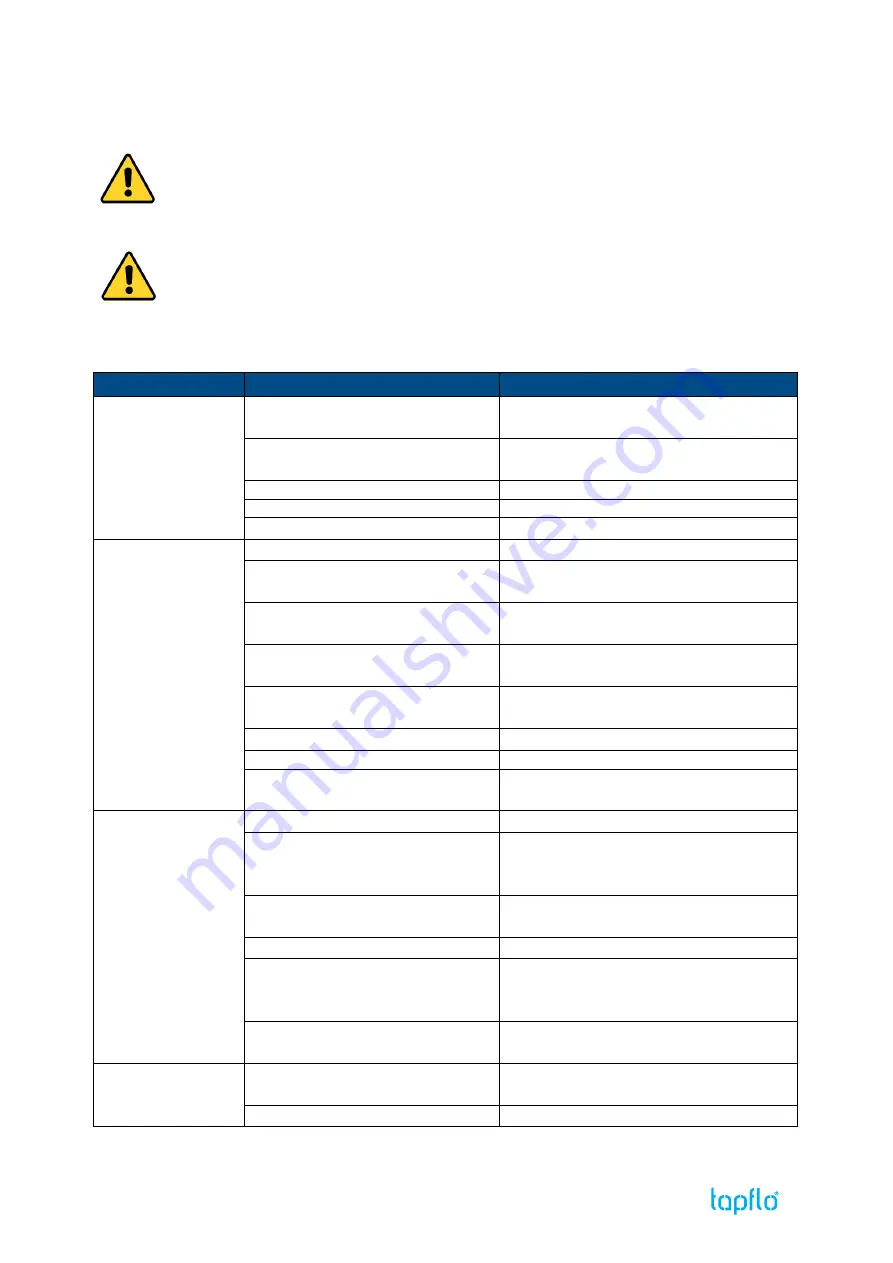

Symptom

Possible cause

Countermeasure

Pump fails to start

No power is supplied (i.e. power

outage)

Contact the electric power company or an

electrical repair shop

Open circuit or poor cable connection

Check if there is an open circuit in the cable or

wiring

Float is obstructed

Remove obstruction and check float operation

Float switch malfunction

Replace the float switch

The impeller is blocked

Inspect the pump and remove the obstruction

Pump starts but stops

immediately causing

the motor protector

to actuate

The impeller is blocked

Inspect the pump and remove the obstruction

Voltage drop

Correct the voltage to the rated voltage or use

an extension cable that meets the standard

Circle thermal protector or protective

device failure

Replacement or adjustment

A 50 Hz model is operated at 60 Hz

Check the nameplate and replace the pump or

the impeller

The strainer is obstructed, and the

pump was operated dry for long time

Remove the obstruction

Broken motor

Repair the motor or replace with a new motor

Low head and high liquid density

Check motor power consumption

The pump is picking up too much

sediment

Place a concrete block under the pump to

prevent the pump from picking up sediment

The pump´s head

and

capacity decreased

The impeller or suction cover is worn

Replace

The hose may be kinked or clogged

Minimize the number of bends in the hose (in

an area with a large amount of debris, use the

pump in a meshed basket)

The pump submerge depth is too

shallow, the air enters the pump

Adjust the submerge depth until the pump is

submerged

The valve on discharge line is closed

Open the valve

The strainer is obstructed or buried

Remove the obstruction; place a concrete

block under the pump to prevent the pump

from picking up sediment

The motor rotates in reverse direction

Interchange the power supply terminal

connection

The pump generates

noise or vibration

The bearing of the motor may be

damaged

Replace the bearing, contact Tapflo

The shaft is bent

Contact Tapflo