1.

INSTALLATION

IOM manual CTX centrifugal pumps

10

1.9.

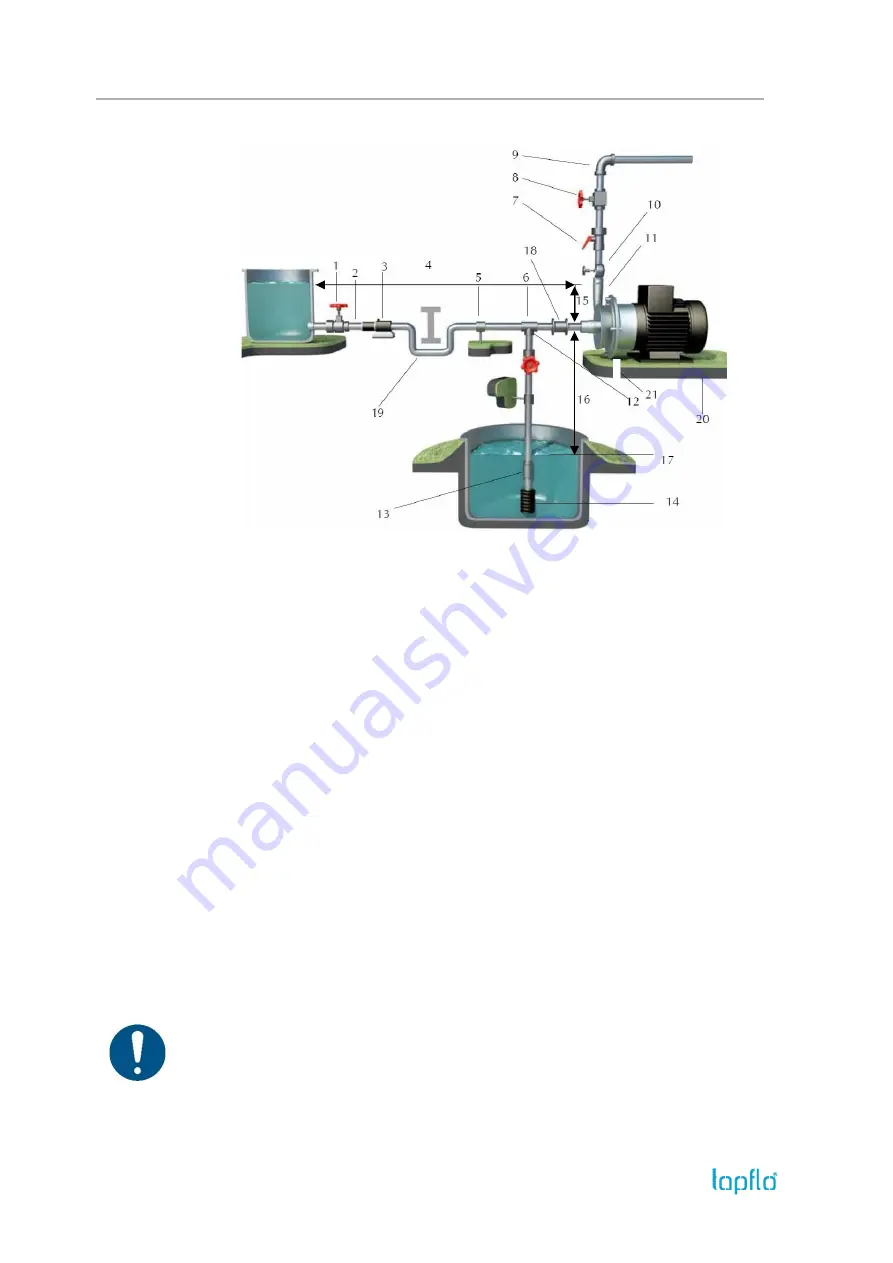

Example of installation

1)

YES: Gate valve (may also be near pump in case of long piping)

2)

With positive head: tilt of piping towards pump

3)

YES: line strainer if particles are present

4)

NO: air pockets

–

the circuit must be short and straight

5)

YES: pipe fastening

6)

Suction line as short and direct as possible

7)

YES: attachment for gauge or safety pressure switch

8)

YES: adjusting gate valve on outlet

9)

Bends placed after valves and instruments not closer to the pump inlet than five times the piping diameter

10)

YES: attachment for gauge or safety pressure switch

11)

NO: elbow joints (and other parts) on the pump (discharge and suction lines)

12)

With negative suction lift: tilt of piping towards suction tank

13)

YES: check valve (with negative suction lift)

14)

YES: strainer if particles are present

15)

Suction head varies according to flow in order to prevent windage

16)

Suction head

17)

Immersion depth

18)

YES: expansion joint (indispensable with long pipes or hot liquids) and/or anti-vibration facility during

discharge and suction; anchored near to pump

19)

YES: overcoming obstacles at lower depths

20)

Fix the pump by the fixing holes provided: the supports must be level

21)

YES: drainage channel around base

1.10.

Instruments

In order to ensure a proper control of the performance and the conditions of the installed

pump, we recommend using the following instruments:

- a pressure-vacuum gauge on the suction piping;

- a pressure gauge on the discharge piping.