14

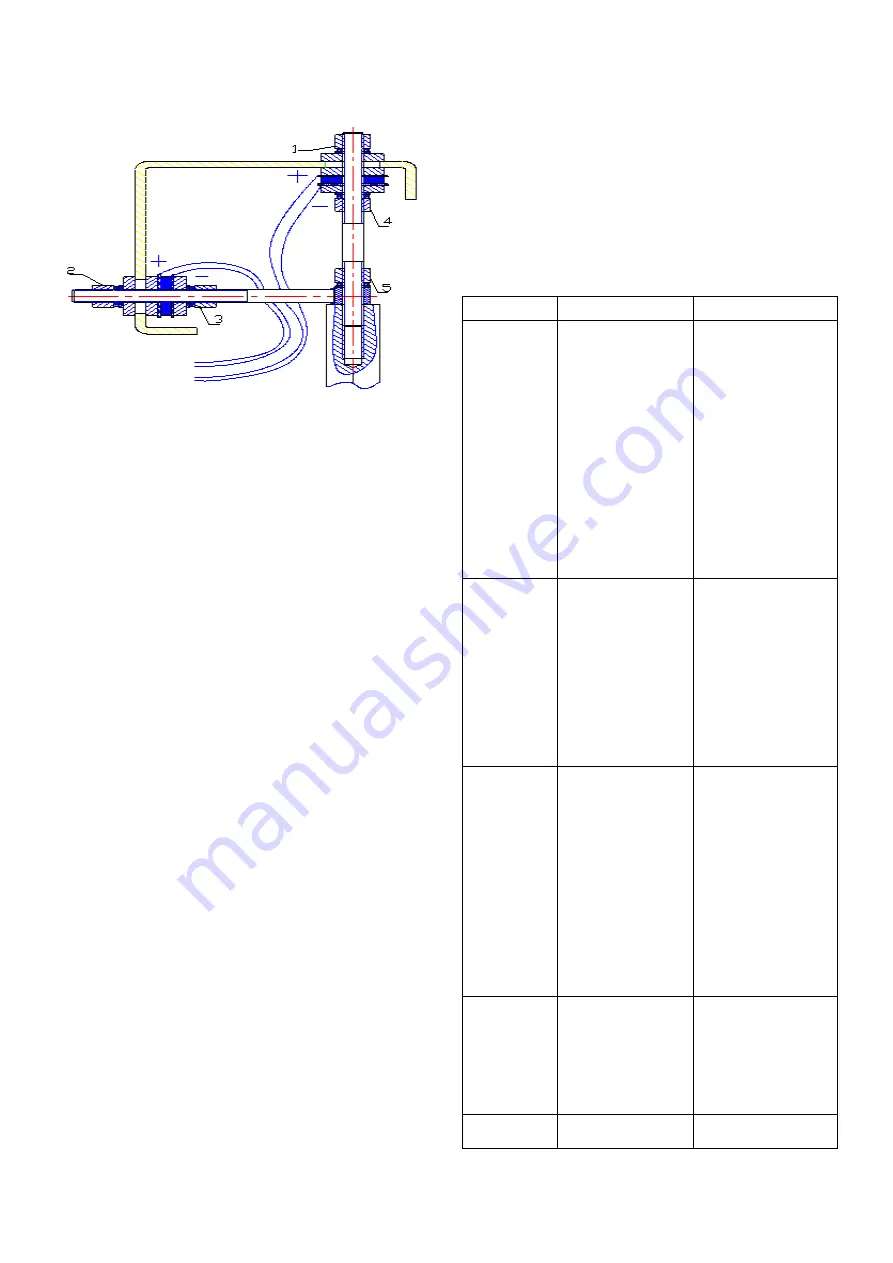

7.3 PRESS SENSOR INSTALLATION AND WIRING

Sometime, the troublesome of inaccuracy of balancing

and position if because the damage of the press sensor.

The method to change the press sensor is shown in the

following:

●

Demount the upper cover and right side panel of the

wheel balancer.

●

Remove the nut 1&2, elastic washer, sanding washer

and plain washer.

●

Loose the nut 3, 4 and 5 to disassemble each part.

●

Change the new sensor and mount the double head

screw and tight the nut 5.

●

Use the spanner to tight nut 4 slightly and then tight

nut3. At this time, pay attention that the horizontal and

vertical sensor screw should to perpendicular to each

other. The end of the screw should fall into the center of

the hole with the gap of at least 1mm.

●

Mount the plain washer, sanding washer, elastic

washer and nut1 and 2. It must be completely tight.

Generally speaking, you should fix the nut1 first and

then nut 2.

)

●

There is the glass glue protective coating on the

pressure sensor.

●

Short cut connect of press sensor output cable to

discharge and then plug the cable discharged into the

computer board to avoid the high voltage to break down

the computer board.

●

Plug the sensor plug according to the original

position.

●

Calibrate the balancer once again and mount the

upper cover and side panel.

After change the computer board, phase sensor or the

press sensor, you must execute the self-calibration. In

the process to change the computer board, you should

setup the parameter according to the parameter

marked in the machine or the original board. You must

self-calibrate after changing

7.4 GENERAL TROUBLESHOOTING & SOLUTION

:

:

Description

Cause

Solution

Start the

machine but

not display.

1.

Check the

circuit of 220V is

normal or not.

2.

power board

fault

3.

The cable

between the power

board and

computer loose

4. computer board

fault

1. Check and

connect the external

power source.

2. Changer the

power board

3. Check the plug

cable

4. Change the

computer board

Display is

normal but

the start

button and

input push

button not

working.

1.

contact switch

not good

2. machine

breakdown

1. Open the housing

of the machine and

plug in and tight the

contact switch plug.

2. Start the machine

again

Display is

normal but

not braking

after start.

1. The cable

between the power

board and

computer lose 2.

power board fault

2. Brake resistor

damage

3. computer

board fault

1. Plug in and tight

the cable between

the computer board

and power board.

2.Change the power

board 3. Change the

computer board

Balance is

not accurate

& difficult to

reach “00”

1. sensor lead

connects or contact

no good

2. memory value

lost

1. Connect again 2.

Correct the memory

value according to

the manual.

Each spin,

1. There are

1. Change the

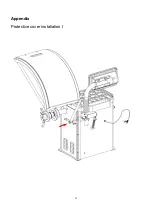

Summary of Contents for Plus 2

Page 1: ...I ...

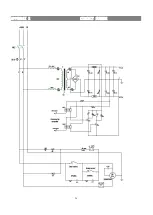

Page 27: ...25 APPENDIX 1 POWER DOARD LAYOUT ...

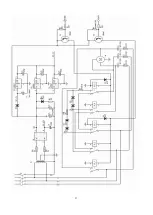

Page 28: ...26 APPENDIX 2 CIRCUIT SCHEME ...

Page 29: ...27 ...