48

Chapter

4

Configuration Overview

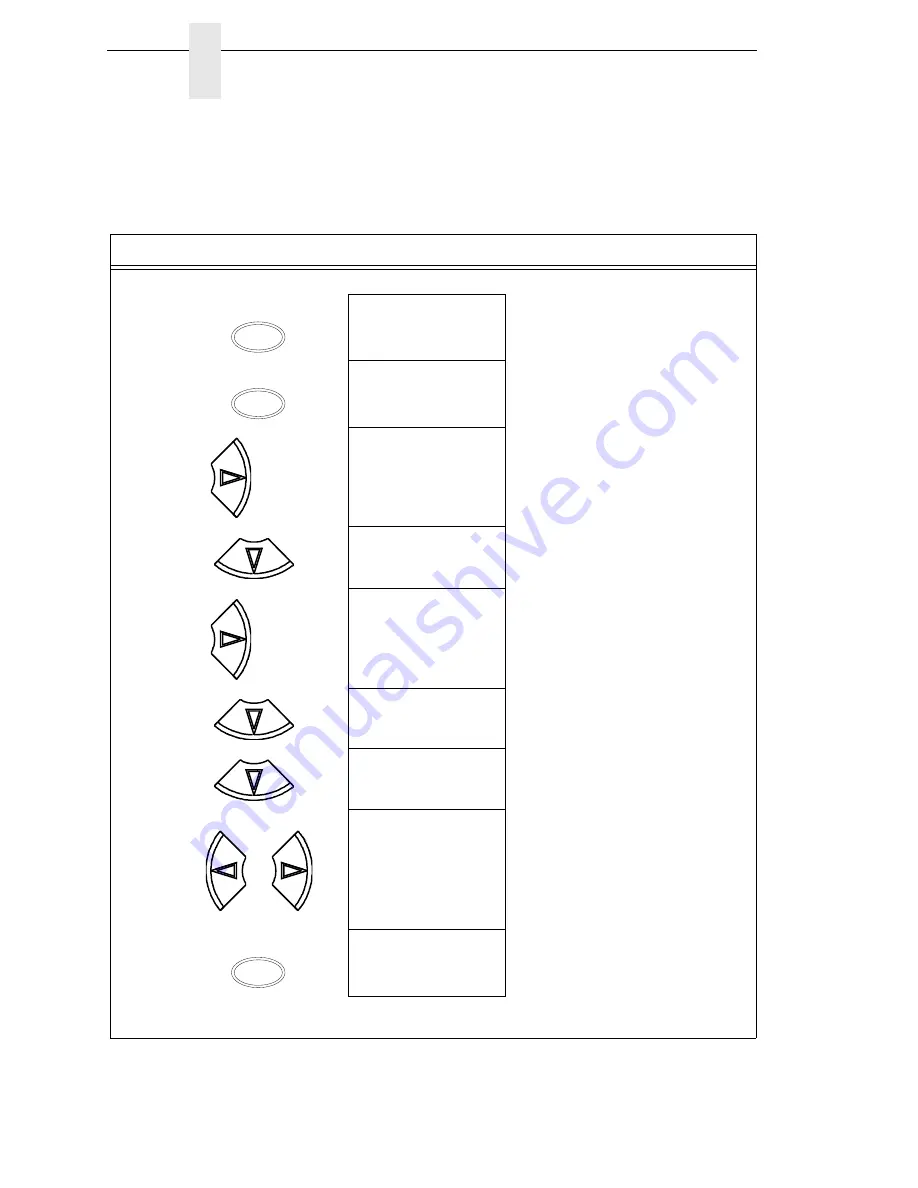

Example 1

This example shows how to save a configuration as a numbered

configuration, then later print it.

Step

Press

LCD

Notes

1.

Make sure the printer is on.

2.

OFFLINE

3.

OFFLINE

QUICK SETUP

Press to enter Menu mode.

4.

OFFLINE

CONFIG MENU

5.

CONFIG MENU

PRINTER

6.

CONFIG. MENU

CONFIGURATIONS

7.

CONFIGURATIONS

Save Config.

8.

Save Config.

CONFIG 1*

9.

Save Config.

CONFIG 2

Cycle through the choices.

10.

Save Config.

CONFIG 2*

The * indicates this choice is active.

NOTE:

We recommend that you print the configuration. To print the configuration go to step 11. To skip this

procedure and resume printer operation, go to step 19.

ONLINE

MENU/ENTER

UNTIL

UNTIL

OR

MENU/ENTER

Summary of Contents for 6605

Page 1: ...TallyGenicom 6600 Series Printers User s Manual ...

Page 3: ...User s Manual TallyGenicom 6600 Series Printers ...

Page 14: ...14 Chapter 1 Contact Information ...

Page 114: ...114 Chapter 5 RS 232 Serial Interface ...

Page 150: ...150 Chapter 7 Diagnosing Problems ...

Page 158: ...158 Appendix B ...

Page 170: ...170 Appendix C Performance Limitations ...

Page 176: ...176 Appendix D Stacker Operation ...

Page 196: ...196 Appendix G Software License Agreement ...

Page 211: ......

Page 212: ...255552 001B 255552 001 ...