Tally Dascom DL-820

User Guide V1.0

15

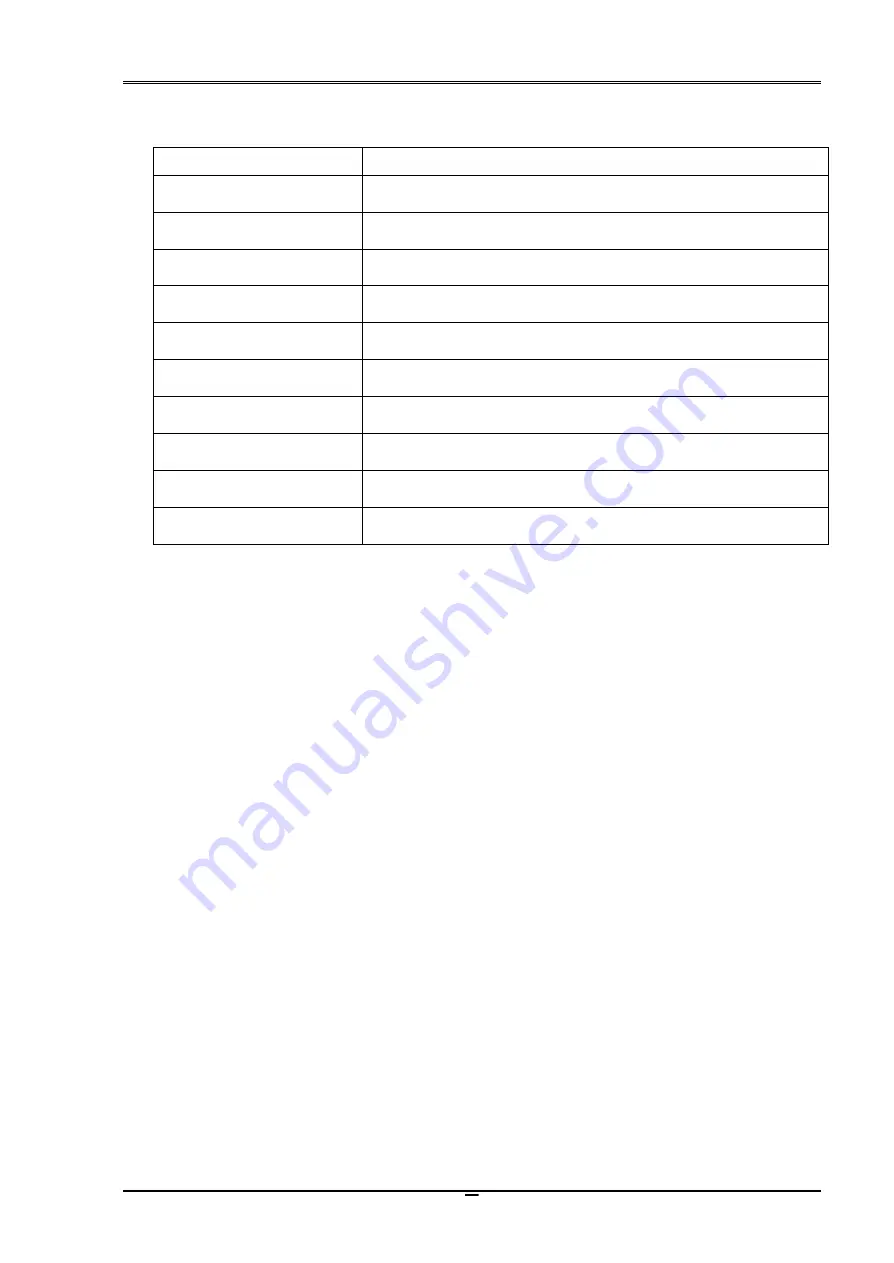

1.9 Displayed error messages

Besides showing the Normal status, the LCD displays error messages when faults occur:

LCD Message

Causes

Print Ready

Setup

The printer is in good operating condition and ready to print.

Pause

Setup

The

▎▎

or ■ button on the Control Panel is press.

Head hot

Setup

This warns abnormal print head temperature.

Head Up

Setup

The print head is lifted up.

Paper Out

Setup

This warns out of media.

Calibrate Error

Setup

This warns not able to detect media present.

Calibrate Error

Setup

This warns jammed media.

Ribbon Out

Setup

This warns ribbon ended.

Ribbon Out

Setup

This warns slipping ribbon winding.

Cutter Error

Setup

*This warns cutting action is interfered by foreign objects.

* Valid if auto-cutter option is installed.