7

installation manual

7. REFRIGERANT PIPE CONNECTION

7.1 Expel The Air

Locate The Pipe

Drill a hole in the wall (suitable just for the size of the wall conduit,

90mm in general), then set on the fittings such as the wall conduit

and its cover.

Bind the connecting pipe and the cables together tightly with

binding tapes. Do not let air in, which will cause water leakage

by condensation.

Pass the bound connecting pipe through the wall conduit from

outside. Be careful of the pipe allocation to do no damage to the

tubing.

Connect the pipes.

Then, open the stem of stop valves of the outdoor unit to make

the refrigerant pipe connecting the indoor unit with the outdoor

unit fluently flow.

Be sure of no leakage by checking it with leak detector or soap

water.

Cover the joint of the connecting pipe to the indoor unit with the

sound proof/insulating sheath (fittings), and bind it well with the

tapes to prevent leakage.

●

●

●

●

●

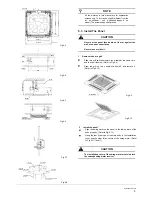

Flaring

Cut a pipe with a pipe cutter.

Insert a flare nut into a pipe and flare the pipe.

Fig.7-1

Fig.7-2

Fig.6-1

Use refrigerant oil

Bend the pipe with thumb

Make the ends

straight

Fig.6-3

Fig.6-2

R0.4~0.8

45 ° ±

2

90 °

± 4

A

Lean crude burr

●

●

Fasten the nut

Put the connecting tubing at the proper position, wrench the

nuts with hands then fasten it with a wrench. (Refer to

Fig.7-3

)

Too large torque will harm the bellmouthing and too small will

cause leakage. Please determine the torque according to

Table.7-2.

Outside diameter

A(mm)

Max

8.7

Φ6.4mm

Φ9.5mm

Φ12.7mm

Φ15.9mm

Φ19.1mm

12.4

15.8

19.0

23.3

8.3

12.0

15.4

18.6

22.9

Min

Table.7-1

Torque

Tubing size

14.2~17.2N.m

32.7~39.9N.m

49.5~60.3N.m

61.8~75.4N.m

97.2~118.6N.m

Φ6.4mm

Φ9.5mm

Φ12.7mm

Φ15.9mm

Φ19.1mm

Table.7-2

Fig.7-3