6

installation manual

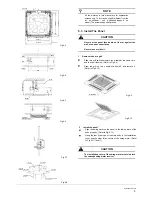

Fig.5-11

Fig.5-13

Fig.5-12

Body

Panel foam2

Ceiling

Panel foam

Air plate

Panel

Panel foam1

Panel sealing foam

Inlet air

Outlet air

Ceiling

Leakage

Dew

Install the panel on the main body with bolt (M5×16) and

washer.

(Refer to Fig.5-11 )

Adjust the four panel hook screws to keep the panel

horizontal, and screw them up to the ceiling evenly.

Regulate the panel in the direction of the arrow in

Fig.5-11.

slightly to fit the panel's center to the center of the ceiling's

opening. Guarantee that hooks of four corners are fixed well.

Keep fastening the screws under the panel hooks, until the

thickness of the sponge between the body and the panel's

outlet has been reduced to about 4~6mm. The edge of the

panel should contact with the ceiling well.

(Refer to Fig.5-12)

3

4

Malfunction described in

Fig.5-13

can be caused by

inappropriate tightness the screw.

If the gap between the panel and ceiling still exists after

fastening the screws, the height of the indoor unit should

be modified again.

( Refer to Fig.5-14-left)

You can modify the height of the indoor unit through the

openings on the panel's four cor ners, if the lift of the

indoor unit and the drainpipe is not influenced

(Refer to

Fig.5-14-right).

Hang the air-in grill to the panel, then connect the lead

terminator of the swing motor and that of the control box

with corresponding terminators on the body respectively.

Relocate the air-in grid in the procedure of reversed order,

install the air-in grid.

Cover

Steel rope

Swing motor installation cover

1

2

3

Cover

Steel rope

Swing motor installation cover

1

2

3

Swing motor side

Drain side

Bolt, washer

4

3

Fig.5-14

Hexagon nut

Ceiling

Horizontal adjust ment

Please operate according

to the direction of the arrow,

or it can not be disassembled

when it is necessary.

Connect the indoor unit at first, then the outdoor unit.

Bend the tubing in proper way. Don’t harm them.

Daub the surfaces of the flare pipe and the joint nuts with

refrigerant oil, and wrench it for 3~4rounds with hands before

fasten the flare nuts. (Refer to

Fig.6-1

)

Be sure to use two wrenches simultaneously when you connect

or disconnect the pipes.

The stop valve of the outdoor unit should be closed absolutely

(as original state). Every time you connect it, first loosen the nuts

at the part of stop valve, then connect the flare pipe immediately

(in 5 minutes). If the nuts have been loosened for a long time,

dusts and other impurities may enter the pipe system and may

cause malfunction later. So please expel the air out of the pipe

with refrigerant before connection.

Expel the air (refer to the “Expel The Air”) after connecting the

refrigerant pipe with the indoor unit and the outdoor unit.Then

fasten the nuts at the repair-points.

Notices For bendable pipe.

The bending angle should not exceed 90°C

Bending position is preferably in the bendable pipe. The larger

the better it is .

Do not bend the pipe more than three times.

Bend the connecting pipe of small wall thickness.

Cut out a desired concave at the bending part of the insulating

pipe.

Then expose the pipe(cover it with tapes after bending).

To prevent collapsing of deforming, please bend the pipe at its

biggest radius.

Use bender to get a small radius pipes.

Use the market brass pipe.

Be sure to use the same insulating materials when you buy the

brass pipe. (More than 9mm thick).

●

●

●

●

●

●

●

●

●

Ĺ

●

ķ

ĸ

6. INSTALL THE CONNECTING PIPE

Check whether the height drop between the indoor unit and

outdoor unit, the length of refrigerant pipe, and the number of the

bends meet the following requirements:

The max height drop and The length of refrigerant pipe deponding

on the ouotdoor unit.(If the height drop is more than 10m, you

should put the outdoor unit over above the indoor unit.)

The number bends fewer than 15

Do not let air, dust, or other impurities fall in the pipe system

during the time of installation.

The connecting pipe should not be installed until the indoor and

outdoor units have been fixed already.

Keep the connecting pipe dry, and do not let moisture in during

installation.

The Procedure of Connecting Pipes

Measure the necessary length of the connecting pipe, and do the

following:

●

●

●

●

●