21

W5

Smart

All rights to changes reserved.

2020-11-19

For users of the Swegon CASA ventilation unit

Thank you for your excellent choice of energy efficient ventilation for your home. Swegon designs, manufactures, mar-

kets and sells Swegon CASA ventilation units and cooker hoods. Swegon guarantees the functionality of the manufac-

tured units and grants a warranty for them. A ventilation system is a unified whole composed of several system compo-

nents all of which influence how the system operates. This check list is meant for use by specialists in the building trade

and for residents who suspect malfunctions in the ventilation.

Malfunctions in ventilation performance

A malfunction in ventilation performance could be caused by any component of the ventilation system or by the way the sys-

tem has been installed. Normal operation of the Swegon CASA ventilation unit is described in the user's instructions supplied

with the unit on delivery. If malfunctions occur in the ventilation system, ensure the following with the help of a professional:

CHECK LIST

If the above-stated checks are not carried out and representatives for Swegon or an authorized service company dis-

cover inadequacies in them, the client is responsible for the costs for the service visit, even during the warranty period.

If a ventilation unit under warranty is still marred by functional disruptions after the checks, submit a contact request

on our web site www.casahelp.fi. If a problem or a fault occurs on the ventilation system after the warranty period

(2 years), contact our network of authorised service companies on www.swegonhomesolutions.se, your real estate

company’s service division or another service company that is fully conversant with ventilation repairs.

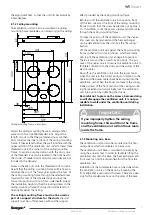

1)

Make sure that the pipes have been insulated fully according to the instructions and that the insula-

tion reaches all the way up to the ventilation unit so that no uninsulated surface is visible.

-> Even a small gap in the insulation could cause among others condensation and acoustic problems.

2)

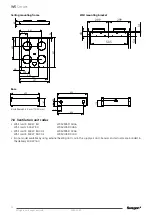

Make sure that the pipes' connections to the ventilation unit are tight and that the unit is installed

horizontally.

-> If the connections have not been fitted correctly, condensation and acoustic problems could arise.

3)

Make sure that the ventilation unit is equipped with Swegon's original filters (www.casastore.

fi). This will ensure pressure differentials and the filtration values that conform to the design level,

enable the unit to operate correctly and maintain a healthy indoor climate in the home. Make also

sure that the filters are clean and replace them when needed. Check also the outdoor air grille and

clean it if needed.

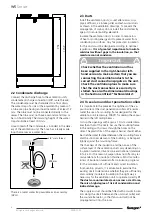

4)

Check that there are no unnecessary objects or impurities inside the ventilation unit. At the same

time, make sure that the condensate drain in the bottom of the ventilation unit is not clogged by

impurities or insects. The condensate drainage function can be checked by pouring a few drops of

water on the bottom of the ventilation unit.

5)

If the ventilation unit is equipped with electric air heaters, make sure that the excess temperature

cutout switches have not tripped. The excess temperature cutout can be manually reset by pressing

a button according to the user's instructions.

6)

Make sure that the ventilation unit's inspection cover is closed and that it seals tightly along its

entire periphery against the unit casing.

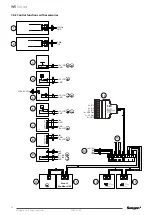

7)

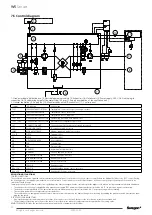

Check that the air flow rate settings have been set according to the ventilation plan and that the air

flow rates to and from the ventilation unit's air heater are in balance (the supply air flow must be

2–10 % less than the extract air flow).

8)

Make sure that the fan speeds have been preset for all the operating modes (Away, Home, Boost).

If the fan speed settings do not deviate from the factory settings presented in the instructions, there

is reason to suspect inadequate commissioning/adjustments.

9)

Make sure that a correctly recorded and approved measurement record is available.

Item to check