Tray One

User’s Manual

Usage

2-2

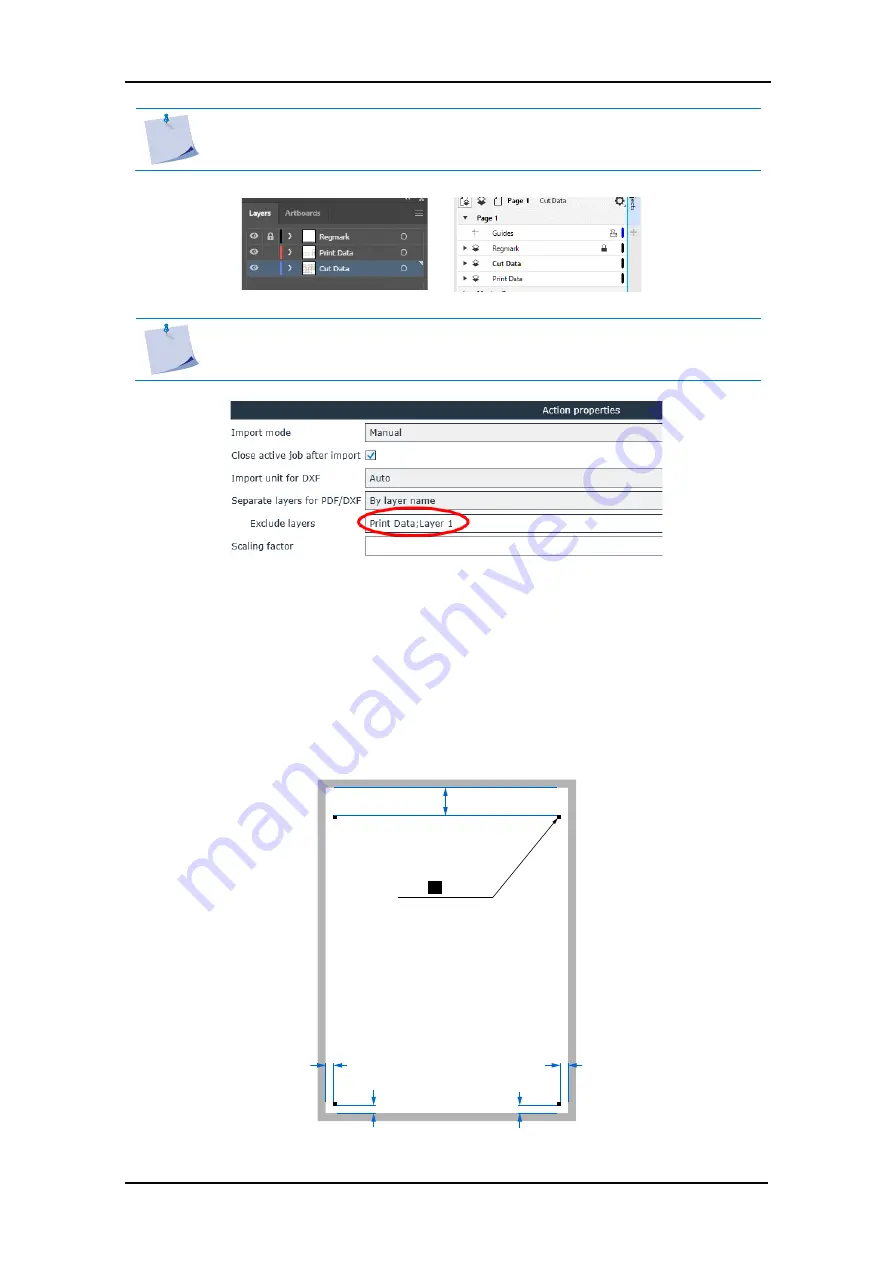

NOTE

: Recommended layer names are:

Print Data

for the layer with the print data.

Regmark

for the layer with the registration marks on them

NOTE

: If the layer name of the layer with the print data is always the same, then

there is a setting in GoSign to ignore the data from this layer. This makes it

unnecessary to disable the layer before exporting.

A template can be made if the plug-in is not used. Easiest is to make a template with the marks

as far outward as possible so that he maximum space of the sheet can be used. When making

this template, please take in account the margin settings in your printer driver and/or the

limitations of the printer. Best way is to make a template, print that blank template out. Measure

the distances between the marks and the sheet edges and adjust the template if needed.

The minimum distances between the marks and edges of the sheets are 10mm at both sides

and at the bottom. The minimum distance ate the top of the sheet need to be 35mm.

35 mm

4 x 3x3mm

2.1.2

Making template if plug-in is not available for your design software

Summary of Contents for TRAY ONE

Page 1: ......