S One

User’s Manual

OPOS

3-4

Normally, the OPOS sensor registers all the marks before it starts cutting. With long cutting

jobs, however, this can lead to extensive back-and-forth shifting of the media, which can result

in poor tracking. To prevent this, an additional parameter can be set in the cutter. This option

divides the job into

segments (“

panels

”)

to prevent the media from being moved around

unnecessarily. When OPOS panelling is activated, all cutting data is cut in segments. The size

of the segments is the distance between the OPOS marks in X direction.

The

OPOS panelling

parameter can be set to

Off

,

On (2 marks)

or

On (4 marks)

. If set to

On (2

marks)

, the cutter will only load up to 2 marks in X direction during an OPOS loading action

and read the marks (4 total for the first segment). The next segments will then be cut after

reading the marks at the end of that segment (i.e. 2 for each subsequent segment). If set to

On (4 marks)

, the last marks of the previous segment are read again, which ensures a better

connection between the segments.

NOTE:

Do not use software panelling when

OPOS panelling

is on.

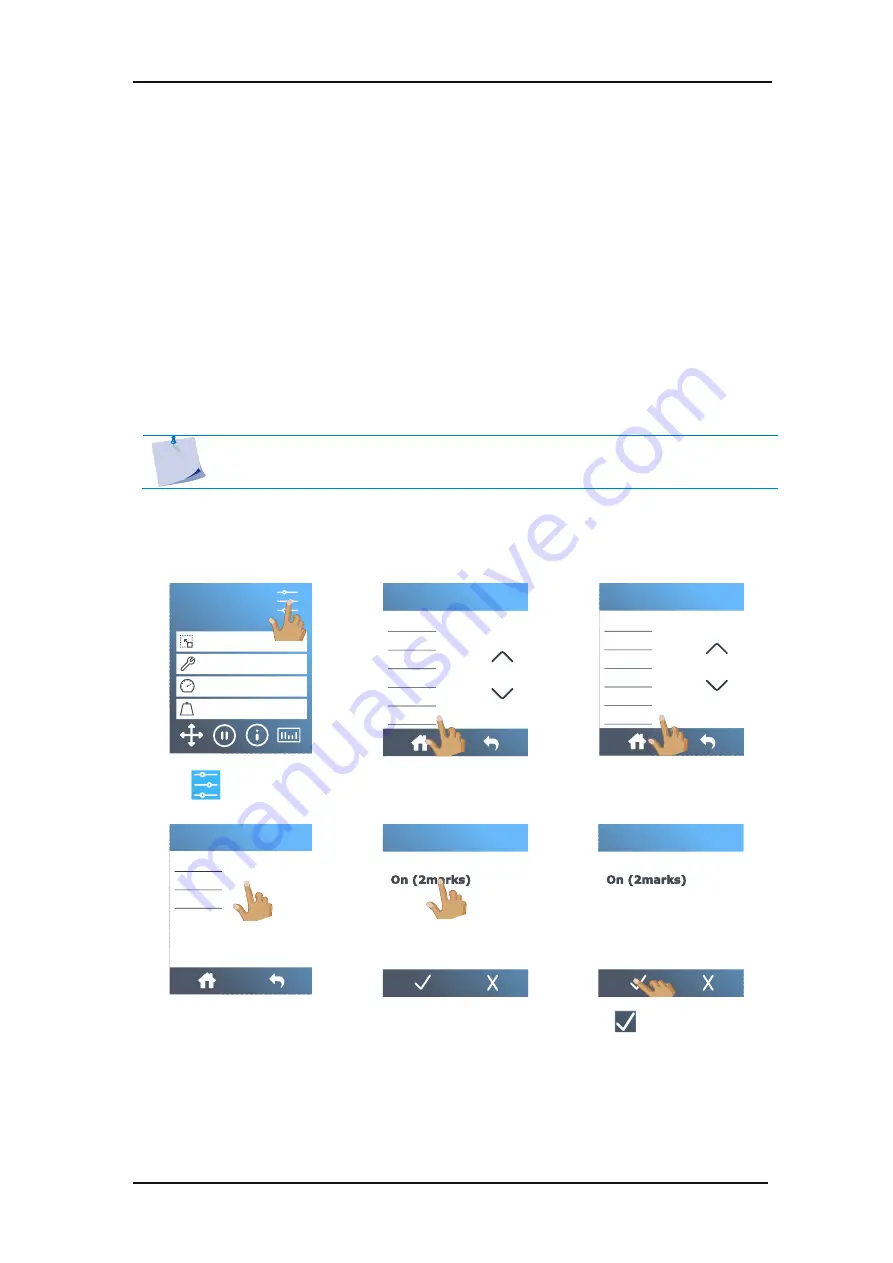

Activating OPOS panelling:

1.

Power on the cutter and load the media.

2.

Tap

.

3.

Scroll down with the arrow

and tap

Configuration

.

4.

Tap

OPOS parameters

.

5.

Tap

OPOS panelling

.

6.

Tap the desired option.

7.

Tap

to confirm.

S1D160

50000 x 145 mm

Knife

700 mm/s

90 g

Configuration 1

LAN 192.168.10.2

FlexCut

Tool

Actions

Settings

Calibrations

Configuration

Menu

Ethernet

Wi-Fi

USB port

Language

Menu units

OPOS parameters

Configuration

OPOS sheet mode

OPOS panelling

OPOS origin

OPOS parameters

Off

On (4marks)

OPOS panelling

Off

On (4marks)

OPOS panelling

3.2.3

Processing long jobs

Summary of Contents for S CLASS

Page 1: ...User Manual Rev 003 ...

Page 52: ......