62

PARTS CATALOG

8.4

COMPRESSOR LUbRICANTS

8.4.1 FACTORY FILL

The compressor is filled with the appropriate amount of lubricant at the Factory before shipment.

Palasyn 45

is the standard lubricant used at the Factory to fill

UD-Series

compressors. A decal, typically located on the

sump tank, indicates the specific lubricant type needed for compressor maintenance. Other lubricants are

available as an optional fill upon request.

8.4.2 OIL COOLANT LIFE VS. OPERATING TEMPERATURE

Fluid Life vs. Operating Temperature is only a guideline for typical oil life if temperature is the only variable

to be considered.

See Figure 8-1.

Many variables affect the oil life, such as environmental impact from various

gases, dust and dirt, compressor short cycling, etc.

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

185

190

195

200

205

210

215

HO

URS

OPERATING TEMPERATURE (°F)

OIL COOLANT LIFE VS. OPERATING TEMPERATURE

Pal-Extra 44

Palasyn 45

Pallube 32P

Pal-32 LL

Pal-Extra 68*

*Pal-Extra 68 is standard for high pressure packages operating between 200-250 psig.

Optimum Operating Temperature Range

FIGURE 8-1.

OIL COOLANT LIFE UNDER DIFFERENT OPERATING TEMPERATURES

Sullivan-Palatek

recommends oil sampling as the best guide for your fluid change interval.

Changing

fluid once a year may not be adequate or it can be excessive. For this reason an hourly service on lubricants

is merely a guide. Please consult your factory-trained servicing Distributor for questions concerning your

lubricant life and Sullivan-Palatek’s

lubricant sampling program. See

6.6 Oil Sample for Analysis on page 49

for additional information.

8.4.3 PALASYN 45

Palasyn 45 is designed for 4500+ hours of use in rotary screw compressors operating in good conditions at

185°F. This product is a specially formulated PAO (polyalphaolefin) synthetic blend for use in a wide variety

of air compressors. Palasyn 45 is used where maximum seal, paint, and plastic compatibility is required and a

significant increase in performance over mineral-based products is desired.

CHARACTERISTICS

»

Good thermal and oxidative stability

»

Excellent anti-wear performance

»

Compatible with most seals, plastics and rubbers

»

Wide operating temperature range

»

Excellent water separation

»

Extended drain intervals reduces oil disposal and increases cost-effectiveness

»

Compatible with most mineral and synthetic oils; non-detergent

FLUID LIFE

Fluid life is maximum hours based on temperature only. Oil change interval to be based on oil per analysis

findings.

»

4,500 hours (or 1 year)

Summary of Contents for UD Series

Page 6: ...vi About This Manual ...

Page 12: ...4 Introduction ...

Page 42: ...34 Component Description ...

Page 52: ...44 Operation ...

Page 66: ...58 Troubleshooting ...

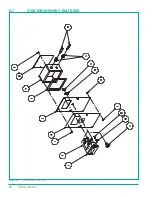

Page 74: ...66 Parts Catalog 8 5 COMPRESSOR FRAME AND DRIVE ASSEMBLY Figure 8 1 AS801 25UD 50UD VFD R00 ...

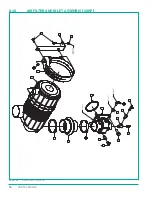

Page 76: ...68 Parts Catalog 8 6 CONTROL ASSEMBLY OPEN Figure 8 2 1072190415 609 R00 ...

Page 78: ...70 Parts Catalog 8 7 STARTER ASSEMBLY ENCLOSED Figure 8 3 AS802 405060 PANEL R03 ...

Page 94: ...86 Parts Catalog 8 15 COOLING ASSEMBLY AIR COOLED Figure 8 11 AS804 50UDAC INLINE R00 ...

Page 100: ...NOTES ...

Page 101: ...NOTES ...