Outdoor Installation (Sheltered)

Many times a compressor must be installed outside due

to available space or other jobsite conditions. When this is

necessary, there are certain items that should be

incorporated into the system to help ensure trouble-free

operation. The unit must be purchased with a TEFC motor.

The standard machine has NEMA 4 rated controls, which

are watertight.

NOTE

Variable speed drive compressors are

NEMA 12 rated and must not be

installed outside or exposed to the

elements.

The compressor should be on a concrete pad, which is

designed to drain water away from it. If the concrete pad

is sloped, then the compressor must be mounted so that

it is level. The base or skid must be sealed where it

contacts the concrete pad.

A weatherhood option should be selected to prevent direct

rain and snow from falling on the unit. If local weather

conditions can be extreme such that direct rain or snow

may fall on the unit, it should be in a fully enclosed room

or building.

If installed under a shelter, air-cooled machines must be

positioned in a way that prevents air recirculation (i.e., hot

exhaust being allowed back to the system air inlet).

In installations that include more than one compressor, hot

air exhaust should not be directed toward the fresh air

intake of the second unit or an air dryer.

A standard machine installed outside must not be started

or run if the ambient temperature in and around the

compressor drops or may drop below 35˚F (1.7˚C).

For installation in a below freezing climate, a low ambient

option with heat tracing and a receiver tank heater must

be installed.

4.3 SERVICE AIR PIPING

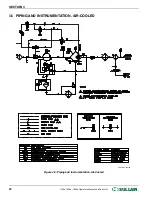

Review carefully the total air system before installing a new

compressor. Items to consider for the total air system

include liquid carryover, pipe sizing, and the use of an

auxiliary receiver. The installation of a drip leg or multiple

drip legs, installation of a line filter(s) and the installation

of isolation valve or valves. These considerations are

important to ensure a safe and effective system.

NOTE

Discharged air contains a very small

amount of compressor lubricating oil,

and care should be taken to ensure

that this oil would not interfere with

downstream equipment.

Pipe Sizing

Pipe should be sized at least as large as the discharge

connection of the compressor. Piping and fittings should

all be suitably rated for the discharge pressure.

Use of Auxiliary Receiver Tank

An auxiliary receiver tank should be used in cases where

large demand swings are expected. This is not necessary

with a variable speed design.

Isolation Valve(s)

If isolation of the compressor from the service lines is

required, isolation valves should be installed close to the

discharge of the compressor. They should be installed

with drip legs that drain sloping downward from the base

in order to drain properly. Install a vent to the piping

downstream of the minimum pressure check valve on the

separator tank, and upstream of the first isolation valve.

When two compressors are operated in parallel, provide

an isolation valve and a drain trap for each compressor

before the common receiver tank.

A built-in after-cooler reduces the discharge air

temperature below the dew point. For most ambient

conditions, considerable water vapor is condensed. To

remove the condensation, each compressor with built-in

after-cooler is supplied with a combination condensate

separator/trap. A drain line should be installed on the

condensate drain.

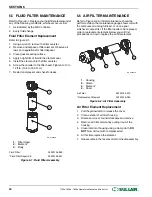

Fluid Containment

Compressors are equipped with a fluid containment pan

to catch any fluid in the event of a leak or spill. The drain

for the pan is located on the air intake end of the machine.

For indoor installations, the drain should be plugged to

contain fluids. For outdoor applications, the drain must be

connected to a separate, customer supplied system to

allow rainwater or any accumulated compressor fluid to

drain out.

SECTION 4

32

1100e, 1500e, 1800e Operator’s Manual and Parts List

®

SULLAIR

®

Summary of Contents for 1107e

Page 101: ...THIS PAGE INTENTIONALLY LEFT BLANK...