Section 6

MAINTENANCE

26

ating pressure which is stamped on the compres-

sor serial number nameplate. The following expla-

nation applies to a typical installation with a desired

operating range of 115 to 125 PSIG (792 to

862kPa). This information will apply to a compres-

sor with any other operating range excepting the

stated pressures.

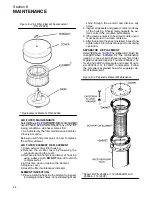

Remove the cover of the pressure switch, pressure

regulator and inlet valve as required. With the

shut---off valve closed (or slightly cracked open)

start the compressor. Observe the line pressure

gauge and pressure switch contacts. When the line

pressure reaches 125 PSIG (862kPa), the pressure

switch contacts should open. If the pressure switch

contacts do not open or they open prior to the de-

sired pressure, the pressure switch setting will re-

quire adjustment (refer to Figure 6---5).

FOR PRESSURE RANGE ADJUSTMENT

:

1. Remove cover to pressure switch.

2. Turn the range adjusting screw to the high pres-

sure setting. Turning the screw counterclock-

wise lowers both the high and low pressure

equally.

FOR DIFFERENTIAL ADJUSTMENT:

Differential is the difference between the high and

low pressure settings. 10 PSIG (7kPa) is typical.

1. Turn the differential adjusting screw to the lower

(reset) setting. Turning the screw counterclock-

wise widens the differential by lowering the reset

(lower) setting only.

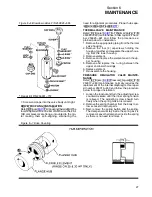

2. When the pressure switch adjustment is com-

plete, the pressure regulator should be adjusted

for the pressure at which modulation of air deliv-

ery should begin. In this case that pressure will

be 118 PSIG (824kPa). The regulator is adjusted

by loosening the jam nut on the end of the cone

shaped cover of the pressure regulator. When

the jam nut is loose, turn the adjusting screw

clockwise to increase or counterclockwise to

decrease the setting.

3. To set the regulator, continue closing the service

valve, until the line pressure is 118 PSIG

(824kPa). At this point regulator should pass a

signal to the inlet valve to start closing it. If the

line pressure keeps on rising or if the modulation

does not begin, adjust the regulator valve as de-

scribed above. After adjustment line pressure

should be approximately 118 PSIG (824kPa)

and 1.00 in. Hg vacuum below the inlet.

4. Now close the service valve, line pressure will

start rising. When line pressure reaches 125

lbs., the inlet valve will be closed to its maximum

position. The inlet vacuum at this point will be

around 25 in. Hg. The machine should unload at

this point.

5. Open the service valve so the line pressure is 115

PSIG (792kPa). Machine is now set for opera-

tion. Recheck the unload pressure by closing of

the service valve. Machine should unload via the

pressure switch at 125 PSIG (862kPa).

After the control pressures have been adjusted, the

“unloaded” sump pressure should be checked. It

will be necessary to shut the compressor down, re-

move the pressure switch cover and disconnect

one of the two lead wires that are connected to the

micro---switch (contact block). After disconnecting

the lead, tape the exposed wire with electricians

tape to make sure that it does not come in contact

with any metallic surface.

DANGER

!

DO NOT touch the electrical contacts, terminal or

leads with any metallic object. Severe electrical

shock may occur.

With the lead taped, you may start the compressor

again. Allow the sump pressure to stabilize.

The sump pressure should read 30 to 35 PSIG (207

to 281kPa).

Once this is checked, shut the compressor down

once again and reconnect the taped lead and re-

place the pressure switch cover. At this time, start

the compressor and cycle the Control System sev-

eral times and re---check all pressure settings and

adjustments.

DANGER

!

DO NOT touch the pressure switch, electrical

contacts, terminal board or leads with any part of

the body or any uninsulated metallic object. Se-

vere electrical shock may occur.

Cycle the Control System several times and re-

check all pressure settings.

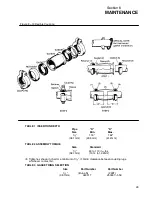

BLOWDOWN VALVE MAINTENANCE

. Blow dow n va lve n o.

250025---655 maintenance is limited to replace-

ment o---rings and the teflon seat. Use repair kit no.

250031---772 and follow the instructions below for

proper installation.

1. Unscrew end caps from the valve body and re-

move.

2. Hold nut with an appropriate socket wrench and

turn screw until loose.

3. Next, remove all internal parts mounted on the

machine screw. Remove the old o---rings and te-

flon seat and discard.

4. Replace with the new o---rings and teflon seat

provided in the repair kit. Apply appropriate lu-

bricant to o---rings and valve body bore.

5. Pre---assemble the internal parts for pilot (P) side

of the valve onto the screw and install into the

body.

6. Assemble remaining internal parts for inlet (I)

side to the screw as illustrated. Once as-

sembled, install the locknut and torque to 25

in.---lbs. (2.82Nm).

Summary of Contents for 10B 25HP

Page 2: ...NOTE For Additional Information on 24KT Units See Inside Back Cover...

Page 4: ...NOTES...

Page 22: ...16 NOTES...

Page 24: ...Section 4 INSTALLATION 18 Figure 4 1 Piping and Instruments...

Page 26: ...20 NOTES...

Page 42: ...36 NOTES...

Page 44: ...NOTES...

Page 45: ......