5

Operation

Lifting

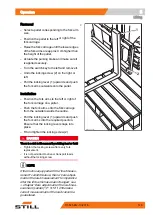

Operation with reversible fork arms

(variant)

DANGER

Risk to life from falling load!

Standard fork arms are not structurally designed for

reverse operation. If this instruction is not observed,

it can lead to material failure and the load falling.

– Only work in reverse operation using reversible

fork arms (1)

WARNING

Risk of accident from slipping load!

Loads may slip on the reversible fork arms if there is

no load support. A fork extension (variant) cannot

be secured against slipping.

– Do not use a fork extension (variant)

WARNING

Risk of accident from the truck tipping over.

When driving, the centre of gravity of the load (2)

must not be higher than 600 mm above the ground.

The truck may tip forwards when driving or braking.

– Only drive with a load centre of gravity up to a

max. of 600 mm above the ground

NOTE

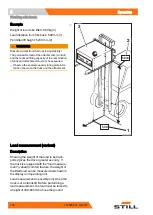

If the truck is equipped with the "load measu-

rement" comfort feature, a "zero adjustment

of the load measurement" must always be

performed after the reversible fork arms have

been changed. Otherwise, correct load mea-

surement cannot be guaranteed.

152

170525 EN - 10/2016

Summary of Contents for RX60-16

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 24: ...1 Foreword Environmental considerations 12 170525 EN 10 2016 ...

Page 25: ...2 Introduction ...

Page 37: ...3 Safety ...

Page 58: ...3 Safety Emissions 46 170525 EN 10 2016 ...

Page 59: ...4 Overviews ...

Page 61: ...Overviews 4 General view of truck 170525 EN 10 2016 49 ...

Page 81: ...5 Operation ...

Page 344: ...5 Operation Cleaning 332 170525 EN 10 2016 ...

Page 345: ...6 Maintenance ...

Page 348: ...6 Maintenance General maintenance information 336 170525 EN 10 2016 ...

Page 352: ...6 Maintenance General maintenance information 340 170525 EN 10 2016 ...

Page 389: ...7 Technical data ...

Page 410: ......

Page 411: ......

Page 412: ...STILL GmbH 170525 EN 10 2016 ...