Safety

2

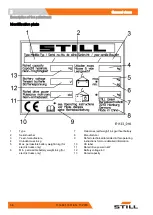

Safety tests

Safety tests

Regular safety inspection of the truck

Regelmäßige Prüfung

(FEM 4.004)

nach nationalen Vorschriften

basierend auf den EG-Richtlinien:

95/63/EG, 99/92/EG, 2001/45/EG

Die Prüfplakette ersetzt nicht das Prüfprotokoll

Nächste Prüfung

56344391019

Mitglied der:

Fédération

Européene

de la Manutention

STILL GmbH Hamburg

0000_003-001_V3

Safety inspection based on time and

extraordinary incidents

The operating company (see chapter entitled

"Definition of responsible persons") must

ensure that the truck is checked by a specialist

at least once a year or after noteworthy

incidents.

As part of this inspection:

• A full check of the technical condition of the

truck in terms of accident safety must be

performed

• The truck must be thoroughly checked to

detect any damage that may have been

caused by improper use

• A test log must be created.

The results of the inspection must be retained

until at least a further two inspections have

been carried out.

The inspection date is indicated by an adhe-

sive label on the truck.

– Arrange for the service centre to perform

periodic safety inspections on the truck.

– Observe the guidelines for tests carried out

on the truck in accordance with FEM 4.004.

The operator is responsible for ensuring that

any defects are remedied immediately.

– Contact your service centre.

NOTE

Observe the regulations in force in your

country.

1133 801 16 01 EN - 11/2018

27

Summary of Contents for ECU 15C

Page 1: ...Original instructions Electric pallet truck ECU 15C 0138 1133 801 16 01 EN 11 2018 ...

Page 2: ......

Page 8: ......

Page 9: ...1 Introduction ...

Page 23: ...Introduction 1 Residual risks 1133 801 16 01 EN 11 2018 15 ...

Page 28: ...1 Introduction Residual risks 20 1133 801 16 01 EN 11 2018 ...

Page 29: ...2 Safety ...

Page 41: ...3 General views ...

Page 45: ...4 Operation ...

Page 61: ...5 Maintenance ...

Page 70: ...5 Maintenance Trouble shooting 62 1133 801 16 01 EN 11 2018 ...

Page 71: ...6 Technical data ...

Page 77: ......