Z001007/0_4_September 2007

Page ELECTRICAL EQUIPMENT-3

ELECTRICAL EQUIPMENT

INSTALLATION INSTRUCTION

16. ELECTRICAL EQUIPMENT

16. 1. GENERAL

Cable laying is to be planned and carried out precisely and carefully. Cables must be approved for marine

operation. Pull the cables through appropriate protective sleeves to be fixed properly. Make sure that cables are

not too close to hot parts of the engine. Cables must not be exposed to mechanical wear and mechanical

abrasion. If necessary, pull the cables through protection tubes.

Attention:

Never fix a cable in such a way that it could lay in bilge water.

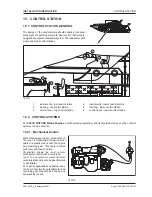

16. 2. BATTERIES

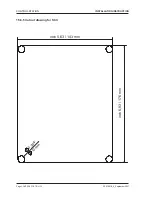

Install the batteries in a battery box situated low in the boat to avoid leaking of battery acid due to motion of the

sea. Provide easy access to the box for servicing the batteries, as well as proper ventilation, as the batteries

generate small amounts of explosive gas.

Install main switches at the positive and negative side. In case of one single switch, install it easily accessible

at the positive side.

Required capacity of main switches:

min. 1000A (short-circuit current)

Attention:

Only bipolar systems may be installed otherwise galvanic streams may occur which cause corrosion.

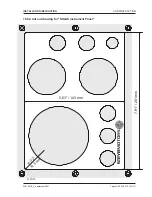

1 air tube, at least 25mm (1"), conducted outwards

2 cover, same material as box

3 clamping bar, which fixes the battery by securing

the nuts (L-iron or flat bar)

4 studs

5 box made of steel plate (min. 3mm) acid-proof

6 clamps with tightening screws (use pole grease)

7 rubber sleeves for cable passage

rated capacity: 12V / 92 Ah

cold test current: 450 A

rated capacity: 12V / 115 Ah

for 24V installation: 2 x 12V/ 115 AH

cold test current: 650 A

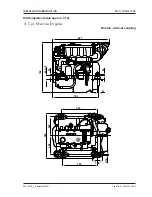

6 Cyl. Engine

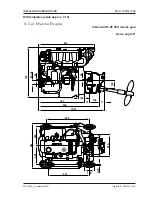

4 Cyl. Engine