Cutting of HARDOX wear plate

Oxygen fuel cutting of HARDOX wear plate

is as simple as cutting of regular Mild Steel.

When cutting of thicker HARDOX plates special

attention is needed. For thick and hard plates the

risk of developing cut edge cracks increases. By

following the recommendations and guidelines

given below cut edge cracking and component

softening can be prevented.

Cutting methods

HARDOX wear plate can very well be cut

using both cold and thermal cutting methods.

The cold methods are abrasive water jet cut-

ting, shearing, sawing or abrasive grinding,

while thermal methods are oxy-fuel, plasma

and laser cutting.

This leaflet contains general suggestions and calculation models. SSAB Oxelösund AB does hereby expressly exclude any liability whatsoever for

their suitability for individual applications. It is the responsibilty of the user of the manual to adapt the recommendations contained herein to the

requirements of individual applications.

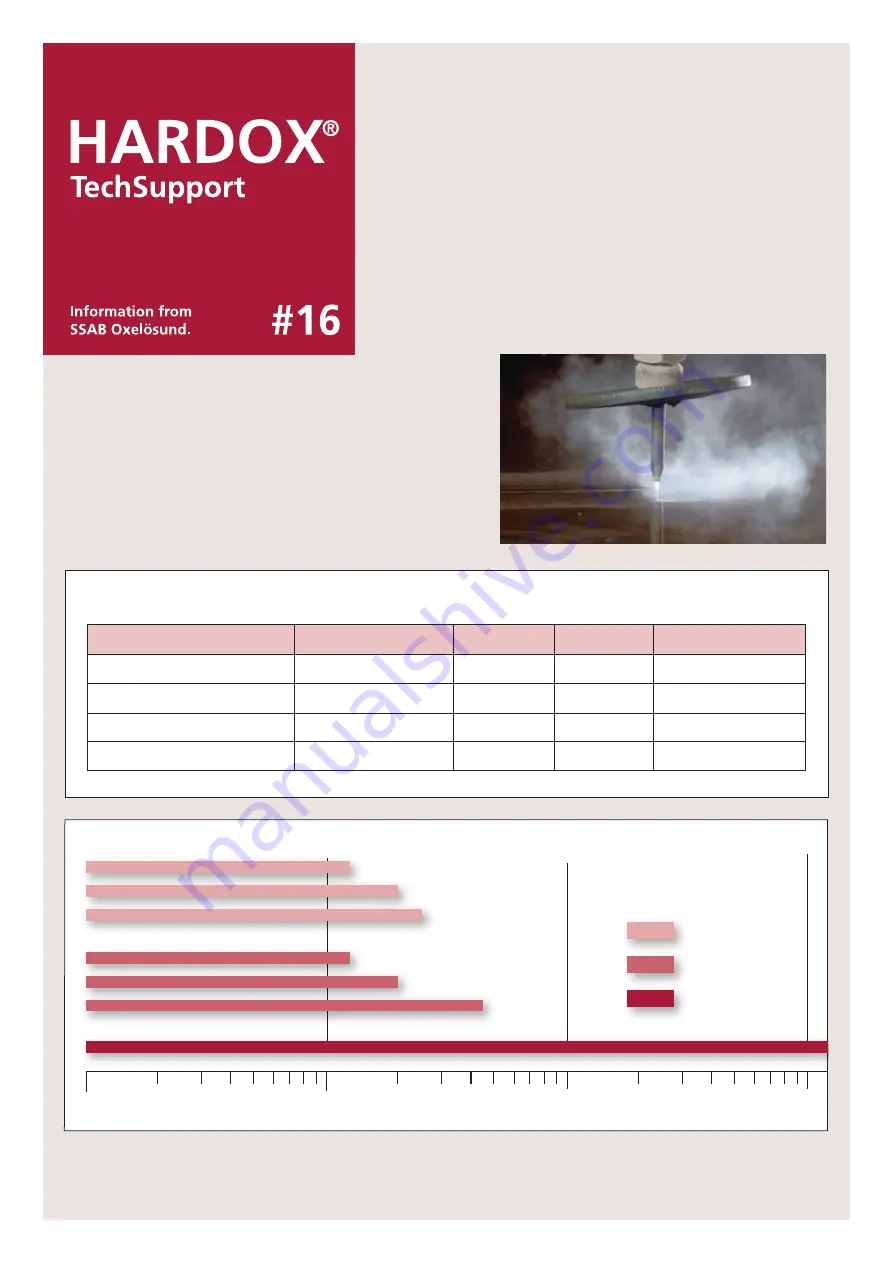

1000

CO

2

Laser

Plasma

Oxy-fuel

1.5 kW

3.0 kW

4.0 kW

100 A

200 A

600 A

Thickness range for different cutting methods

Plate thickness [mm]

10

100

1

1000

Abrasive

water jet

cutting

General features for different cutting methods

Cutting method

Cutting speed

Kerf

HAZ

Dim. tolerance

Abrasive water-jet cutting

8 –150 mm / min

1– 3 mm

0 mm

± 0,2 mm

Laser cutting

600 – 2200 mm / min

< 1 mm

0,4 – 3 mm

± 0,2 mm

Plasma cutting

1200 – 6000 mm / min

2– 4 mm

2– 5 mm

± 1,0 mm

Gas cutting

150 – 700 mm / min

2– 5 mm

4 –10 mm

± 2,0 mm

Table 1

Diagram 1