© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

Installation/Operation Supplement

M414884 (EN)

8

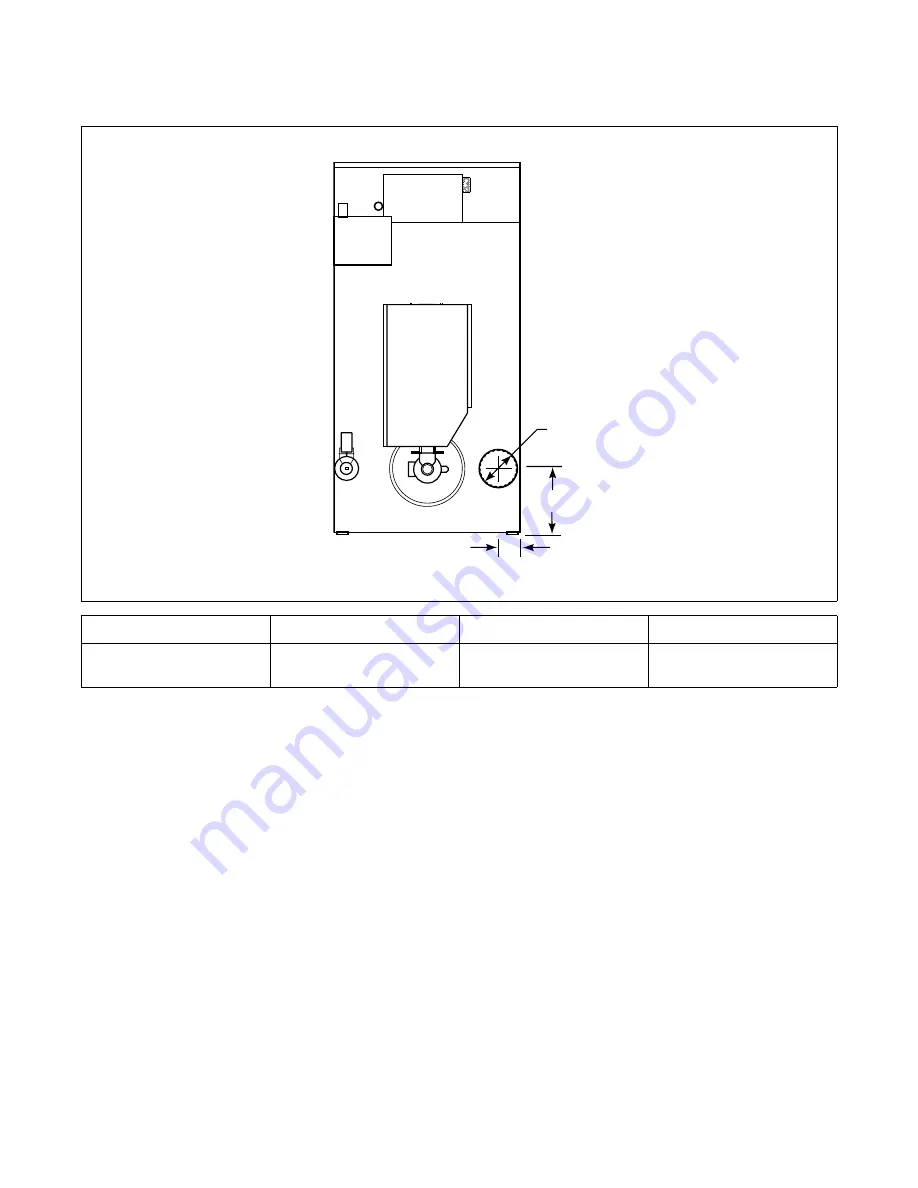

Horizontal Exhaust Outlet Locations

TMB811N

TMB811N

A

B

C

Models

A

B

C

050/075

137 mm

(5.375 in.)

203 mm

(8 in.)

340 mm

(13.375 in.)