MAINTENANCE

-36-

For Machines Mfd. Since 9/20

South Bend Tools

Model SB1092 & SB1094

M A I N T E N A N C E

Maintenance Schedule

For optimum performance from your machine,

follow this maintenance schedule and refer to

any specific instructions given in this section.

Ongoing

To minimize your risk of injury and maintain

proper machine operation, shut down the

machine immediately if you ever observe any

of the items below, and fix the problem before

continuing operations:

• Loose mounting bolts.

• Damaged filter canister, cleaning paddle

components, or collection bags.

• Worn or damaged wires.

• Suction leaks.

• Any other unsafe condition.

Monthly Check

• Clean/vacuum dust buildup off machine body

and motor.

Semi-Annual/Annual Check (Depending on

Frequency of Use)

• Replace canister filter.

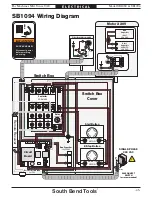

Always disconnect

machine from power before

performing maintenance or

serious personal injury may

result.

!

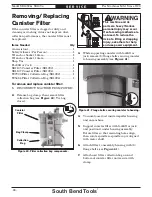

Cleaning Canister

Filter

This dust collector uses an automatic filter

brush to remove dust buildup and debris from

the filter pleats. The system will turn ON for

approximately 90 seconds after the machine is

turned OFF to clean the canister filter and knock

dust cake into the filter bag.

If operating pressure on pressure gauge

drops below 200mmAq, remove canister filter

and gently knock dust from pleats (refer to

Removing/Replacing Canister Filter

on Page 38). If operating pressure reaches

150mmAq and cleaning does not improve

performance, replace the filter.

IMPORTANT:

DO NOT use water or high pressure

to clean canister filter. Doing so will damage the

filter and reduce filtration.

Dispose of the filter collection bag when dust fills

it about

1

⁄

2

full (see Removing/Replacing Filter

Collection Bag on Page 37).

IMPORTANT:

To contain wood dust and minimize

risk of exposure, firmly tie bag closed.

Dust exposure created while

using machinery may cause

cancer, birth defects, or long-

term respiratory damage.

Always wear goggles and a

NIOSH approved respirator

when working with the dust

collection bags or canisters.