-60-

For Machines Mfd. Since 12/21

South Bend Tools

Model SB1007

S E R V I C E

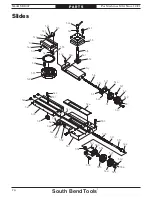

Saddle Gib

Tools Needed:

Qty

Hex Wrench 3mm .................................................1

Before making adjustments to the saddle gib,

make sure the carriage lock (see Figure 44 on

Page 37) is loose by turning it counterclockwise

one full turn.

To adjust saddle gib:

1.

DISCONNECT LATHE FROM POWER!

2.

To tighten saddle gib, tighten set screws (see

Figure 92). To loosen gib, loosen set screws.

Note:

Be sure to adjust all set screws the

same amount. This will ensure even wear of

gib and sliding surfaces.

3.

Move carriage back and forth, repeating

adjustments as necessary, until saddle

movement is acceptable.

Belt Tension &

Replacement

The timing belt transfers power from the motor

to the drive pulley.

Because the molded teeth in the belt fit together

with matching teeth in the pulley, the timing belt

will not slip unless the belt teeth become overly

worn or belt tension is overly loose.

An improperly tensioned timing belt will slip,

which quickly causes it to become damaged

and unsuitable for further use. Therefore, it is

essential to maintain belt tension properly to

prevent slippage.

Once a timing belt begins to slip, it must

be replaced in order to regain proper power

transmission.

Tools Needed:

Qty

Open-End Wrench 17mm .....................................1

Hex Wrench 5mm .................................................1

Hex Wrench 6mm .................................................1

Tensioning Timing Belt:

1.

DISCONNECT

LATHE FROM POWER!

2.

Remove

end gear cover.

3.

Loosen four motor mount hex bolts (see

Figure 93).

Figure

Figure 93. Motor mount bolts.

. Motor mount bolts.

Motor Mount

Motor Mount

Bolts (2 of 4)

Bolts (2 of 4)

Figure

Figure 92. Saddle gib components.

. Saddle gib components.

Set Screws

Set Screws