2-3.

VF Block

2-3-1.

VF Assembly

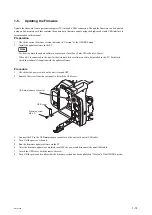

Procedure

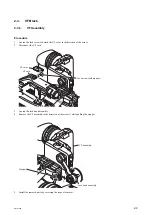

1.

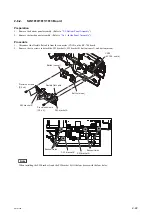

Loosen the lock screw to detach the VF cover in the direction of the arrow.

2.

Disconnect the VF cord.

VF cover

VF cord

Lock screw (with stopper)

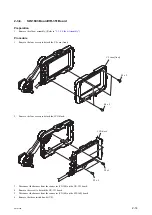

3.

Loosen the lock knob assembly.

4.

Remove the VF assembly in the direction of the arrow A while pulling the stopper.

VF assembly

Lock knob assembly

Stopper

A

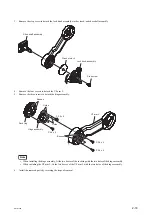

5.

Install the removed parts by reversing the steps of removal.

PMW-300

2-9